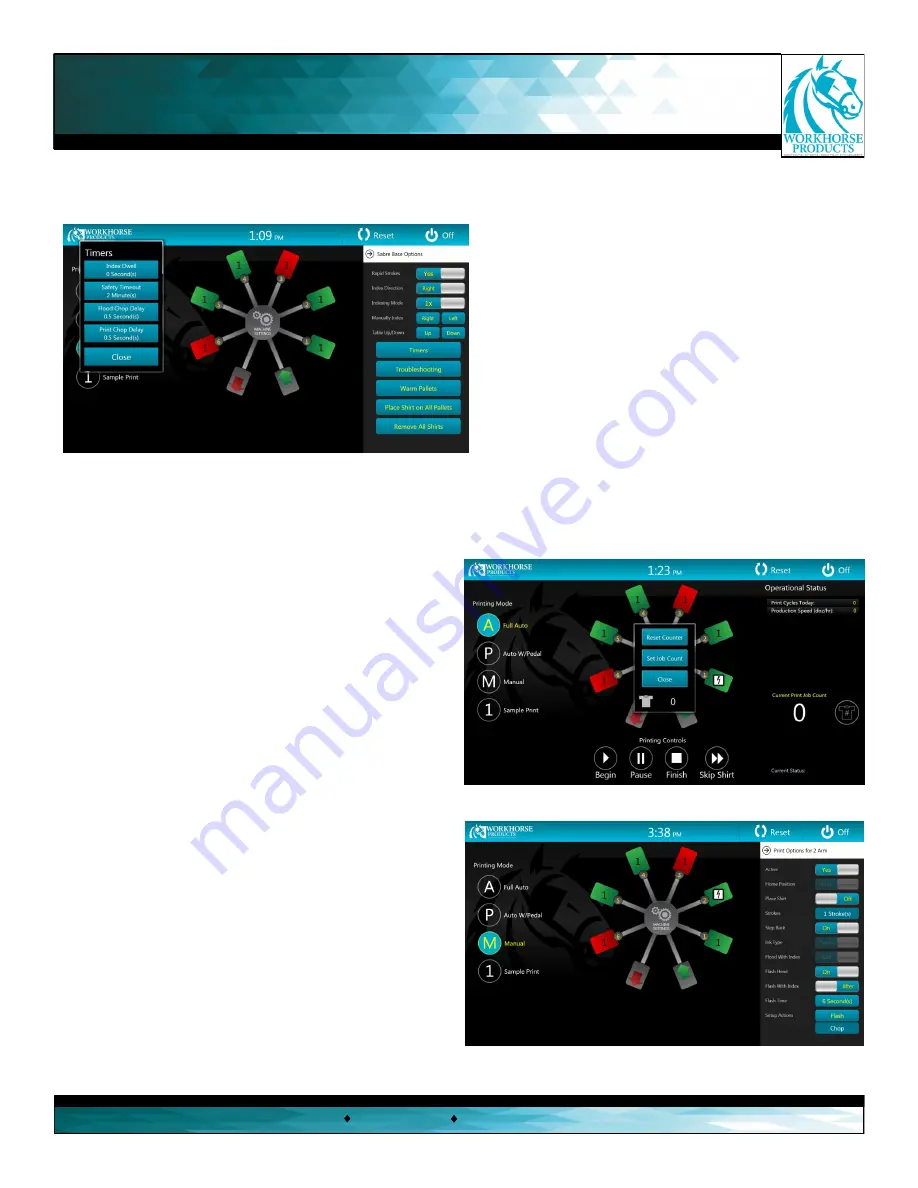

The “Timers” menu allows the operator to set timers that can be used to adjust the press.

“Index Dwell”

- Delays the machine before it indexes

again in (A) “Full Auto” mode. This function slows the ma-

chine to allow more time to unload and load the press

before the print cycle completes.

“Safety Timeout”

- Automatically disables the foot pedal

from starting a print sequence while in (P) “Auto w/ Pedal”

mode if the pedal has not been pressed within the same

amount of time.

“Flood Chop Delay”

- Delays the flood carriage from mov-

ing after the print and chop sequence has completed.

“Print Chop Delay”

- Delays the print carriage from moving

after the flood and chop sequence has completed.

“Close”

- This will close the sub-menu.

To access the “Counter” menu, press the round shirt button

next to the current print job count. A sub-menu will appear

with the following functions:

“Reset Counter”

- Resets the counter back to zero.

“Set Job Count”

- Allows the operator to select the num-

ber of items to be printed before a warning appears and

the machine is paused.

“Close”

- This will close the sub-menu.

The step back function is a powerful feature allowing the

press to perform a print, flash, print, and a second flash while

only using two print heads (instead of four). To activate this

feature, setup one head as a flash and turn “Step Back” mode

on for that head (as seen on the screen capture to the right):

With the settings configured per the example the machine will

perform as below:

1. Forward index and print the item on head 1.

2. Forward index and flash the item that was printed on

head 1.

3. Reverse index and print the same item on head 1.

4. Forward index and flash the same item on head 2.

5. Forward index and print all remaining configured heads.

3730 E. Southern Avenue, Phoenix, AZ 85040 USA

800-778-8779

Workhorseproducts.com

11

Touchscreen Controls