Commissioning

35

Worcester Commercial Boiler Series – 6720814332 (2019/04)

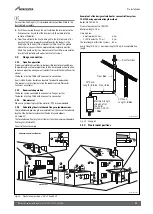

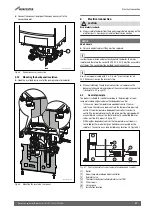

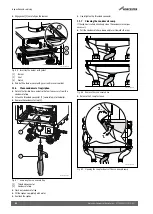

Fig. 68 Connecting the pressure gauge at the 85-V2 and 100-V2

▶ Open the gas isolation valve.

▶ Bring the boiler into operation.

▶ Make sure that the boiler can dissipate the heat generated.

▶ Start the chimney sweep mode (

Chapter 7.3).

▶ Set the output to 100%.

▶ Measure the gas supply pressure.

▶ Enter value in maintenance protocol.

▶ Check that the measured value is not less than the permissible value

(

Never commission the appliance above or below these values. The cause

must be established without fail and the fault rectified. If this is not

possible, shut off the gas supply and contact the gas supplier.

▶ Take the boiler out of operation.

▶ Close the gas isolation valve.

▶ Remove the pressure gauge.

▶ Close test nipple for gas supply pressure.

▶ Open the gas isolation valve.

▶ Bring the boiler into operation.

▶ Check gas tightness of the boiler.

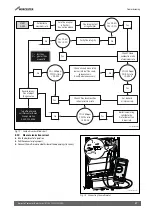

8.8

Measure gas/air ratio

NOTICE:

Damage to the boiler due to incorrect setting.

The gas valve is exceptionally reliable and therefore requires no

adjustment:

▶ Only the gas/air ratio may be measured.

▶ If the measurement is out of spec, the gas valve must be replaced.

▶ Take the boiler out of operation.

▶ Close the gas isolation valve.

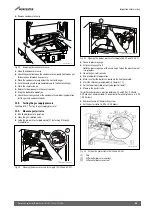

▶ Undo the nozzle pressure test nipple [1] by turning it through

2 revolutions.

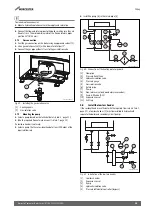

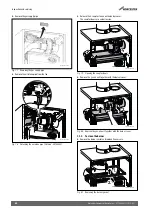

Fig. 69 Open the burner pressure nipple at the 50-V2 and 65-V2

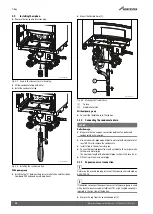

Fig. 70 Open the burner pressure nipple at the 85-V2 and 100-V2

▶ Connect the pressure gauge.

▶ Set the pressure gauge to “0”.

Hold the pressure gauge at the same height when the measurement

is in progress.

▶ Open the gas isolation valve.

▶ Bring the boiler into operation.

▶ Make sure that the boiler can dissipate the heat generated.

▶ Start the chimney sweep mode (

Chapter 7.3).

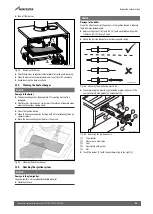

▶ Set the smallest possible output value (partial load).

▶ Measure the gas/air ratio.

This differential pressure must be between -10 and 0 Pa (-0.10 and

0.00 mbar) with partial load. If not, the gas valve must be replaced.

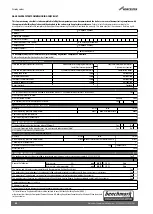

▶ Enter the measurement in the maintenance protocol

(

Chapter 11.15, page 44).

▶ Exit the chimney sweep mode.

▶ Take the boiler out of operation.

▶ Close the gas isolation valve.

▶ Remove the pressure gauge.

▶ Close the test nipple.

▶ Open the gas isolation valve.

▶ Bring the boiler into operation.

0010010029-001

1

0010010030-001

1

0010010032-001

1