28

3064058_201610

AHU TE

AHUW TE

Maintenance

Before undertaking maintenance work, always ensure that the system main isolator and

the repair switch(es) are OFF and locked to prevent unintentional reactivation. Activation

without the knowledge and consent of everyone working on or near the machine could

expose them to risks due to rotating and moving parts.

Always wait for the fan to run down to a complete standstill before opening inspection

doors (waiting time at least 2 minutes). The partial vacuum inside the unit could draw

in loose or slack parts when the door is opened, which could cause severe damage to

the fan. Severe or fatal injury could result if the vacuum sucks items of clothing (such

as a necktie) inside. The airstream of the fan could slam an inspection door open and

cause injury if the fan is installed on the pressure side.

Retension the vee-belts for the first time after approximately one hour in use. Subsequently

check the belts regularly: The interval between checks depends on operating conditions,

but should not exceed 4 months.

Always replace the belts of multi-groove drives as a complete set.

Large drive motors are mounted on adjustable square sections or a motor carrier.

To tension the vee-belt, undo the fixing screws of the square sections and undo the

locknuts on the tensioning screw. Tighten the tensioning screw until the belt is correctly

tensioned, ensuring that the vee-belt pulleys remain in perfect alignment. Tighten the

locknuts and the fixing screws.

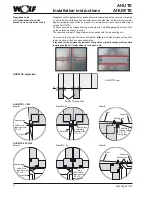

Check that the vee-belt pulleys are in perfect alignment.

Note

Vee-belt

tensioning screw

(appliance with motor carrier)

Fan section

Fan bearings which can be lubricated must be lubricated with lithium based grease for

the first time after approx. 50 hours run and thereafter every 2500 hours run.

Maintenance-free bearings have lifelong lubrication and bear labels to that effect.

Standard three-phase motors are maintenance-free.

In the case of special motors, always comply with the maintenance instructions issued by

the motor manufacturer.

Vee-belt drive

Always replace the complete set of vee-belts if one or several vee-belts require

replacement on a multi-groove drive.

Never use vee-belts from different manufacturers

In a single set of vee-belts.

Check the security of the vee-belt pulleys and the clamping screws of the clamping

bushes.

Check that the vee-belts are correctly tensioned.

Vee-belts tensioned too tightly or too slack can result in fan or motor bearing

damage.

Ensure the vee-belt pulleys are correctly aligned to prevent unnecessary vee-belt wear

and unnecessary bearing loads.

Regularly check the vee-belt tension.

1

0

1

3

4

2

min

>

I

I

I

I

2

0

1