13

1. Safety Information

Before first use, please read the

operating instructions carefully.

These provide important safety

information and information

concerning use and mainte-

nance of the tool.

This precision boring tool is designed

for finishing bores in metallic materials.

Specific information on the machining of

individual metallic materials is not the sub-

ject of these operating instructions. When

used with other materials, please consult

our application engineers and observe the

relevant, applicable safety regulations. The

manufacturer cannot be held responsible

for damage or injury caused by improper

use.

A damaged tool could endanger your safe-

ty! Decommission the tool immediately and

contact your supplier.

This tool complies with the prescribed

safety regulations. Repairs must be under-

taken only by trained personnel. Improper

repairs can represent a considerable risk

for the user. Warranty provisions can be

implemented in the event that original

Wohlhaupter spare parts and accessories

are used.

Keep the operating instructions in a safe

place for future use.

2. Application and operation

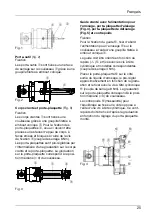

Precision boring tools are designed for

machining holes from Ø 0.4 mm to Ø 152

mm (Ø .016“ – 5.984“).

A wide range of accessories is available for

the individual diameter ranges.

Boring:

• For the Ø 0.4 – 6.5 mm (Ø .016“ – .256“)

range: Mini boring range.

• For the Ø 6 – 27 mm (Ø .236“ – 1.063“)

range: Tool holder made of steel or

carbide metal.

• For the Ø 20 – 53 mm (Ø .787“ – 2.087“)

range: Insert holder with serrated tool

bodies made of steel or carbide metal

• For the Ø 52 – 102 mm (Ø 2.047“ –

4.016“) range: Insert holder for direct

mounting onto precision boring tool

slider.

• For the Ø 68 – 152 mm (Ø 2.677“ –

5.984“) range: Insert holder with Alu-Line

serrated slide and counterweight.

Outside turning:

• For the Ø 4 – 66 mm (Ø .157“ – 2.598“)

range: Insert holder for direct mounting

onto precision boring tool slider.

• For the Ø 2 – 58 (Ø .079“ – 2.283“) mm

range: Insert holder with Alu-Line serra-

ted slides and counterweight.

3. Tool data

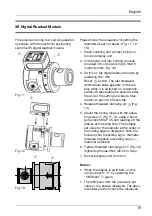

• Precision boring tool with optional digital

display in combination with an electronic

positioning system. In digital mode the

slider‘s adjustment range is measured

directly

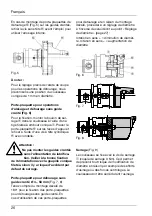

• On the machine side, the precision bo-

ring tool is equipped with a Wohlhaupter

MultiBore connection.

• Precision threaded spindle for precision

adjustment.

• Manual precision balancing through

balancing weights

• Maintenance-free

• Tool comes with Ø 16 mm bore and

K-profile on front of slider for mounting

genuine Wohlhaupter accessories.

• Internal coolant feed up to the cutting

edge. Max. permissible pressure 40 bar.

• Radial adjustment range – 0.1 mm /

+ 2.5 mm (– .004“ / + .098“).

• Storage temperature: – 10 °C to + 65 °C

(14° F to 149° F).

• Operating temperature: + 10 °C to + 40 °C

(50° F to 104° F).

• Weight for MVS 50-28: 0.7 kg (1.3 lbs).

English

Summary of Contents for VARIOBORE 536

Page 1: ......