MI-1075 24

against the spring and closes the throttle to a point

where the engine speed will be maintained practically

constant under varying load conditions. This speed

can be varied to suit conditions by adjusting the

governor spring tension. An idle return spring is

hooked into the upper end of the governor lever and

connected to the breather tube on the tappet cover.

GOVERNOR ADJUSTMENT (Fig’s. 44 and 45)

To maintain correct carburetor throttle opening and

obtain proper governor regulation, the governor lever

must be properly positioned on the fulcrum shaft.

This procedure is only necessary if governor lever

was loosened or removed from fulcrum shaft.

1. Assemble

control rod,

from carburetor throttle lever

to governor lever.

2. Connect

governor spring,

from

adjusting screw

to

hole in

governor lever

. This will hold carburetor

throttle wide open.

3. Loosen governor lever

clamp screw

so that fulcrum

shaft can be turned independently of governor lever.

4. Turn

fulcrum shaft

counter-clockwise until you feel

the internal governor vane stop against the flyweight

thrust pin.

5. Tighten

clamp screw

as illustrated in

Fig. 44

, and

mount

idle return spring

from breather tube to gover-

nor lever as shown in

Fig. 45

.

ENGINE SPEED (Fig. 45)

Engine speed

is adjusted by hooking governor spring

into correct hole of governor lever, and then regulating

spring tension by means of an adjusting screw. The

governor lever has

8

holes for the governor spring,

with the No. 1 hole closest to the fulcrum shaft.

A change in the design of the

governor flyweights

was in-

corporated in TR-10D

engines beginning with Serial

No. 3909152.

Governor regulation is affected as a

result of this change, so in readjusting engine speed,

refer to

Governor Lever Chart, Fig. 45

, for all TRA-10D

engines and if this change is pertinent to your TR-10D

engine.

TR-10D engines built previous to Serial No. 3909152

were set for full throttle operation:

Spring in Hole No. 2

No Load R.P.M. – 3800 Load R.P.M. – 3450

The governor lever chart,

Fig. 45,

shows the

full load

and

no load

speeds and the corresponding governor

spring hole. After hooking spring into the lever hole

relative to the desired

load speed

, run the engine with-

out load and regulate the spring tension by means of

the

adjusting screw

until the required

no load

speed is

obtained. The governor spring will have to be dis-

connected from adjusting screw each time screw is

turned in or out.

A tachometer or revolution counter should be used

against the crankshaft to check speed while adjusting

the governor spring tension. The engine speed with-

out load will be higher than the speed with load. For

instance, if the engine speed is to operate at 3000 R.P.M.

under full load, the speed with no load will be 3230

R.P.M. and this should be kept in mind when adjust-

ing the governor. Refer to the governor lever chart,

Fig. 45,

for the variation between load speed and no

load (high idle) speed.

Summary of Contents for Air Cooled TR-10D

Page 6: ...MI 937 2 4 Fig 1 289860C TAKE OFF rear and LEFT HAND SIDE VIEW of ENGINE...

Page 7: ...5 MI 938 2 FAN END front and RIGHT HAND SIDE VIEW of ENGINE...

Page 8: ...MI 939 2 6 SECTIONAL VIEWS OF ENGINE...

Page 28: ......

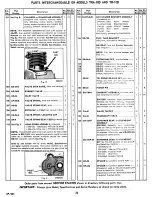

Page 29: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Page 30: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Page 31: ...PARTS FOR ENGINE MODELS TRA 10D AND TR 10D...

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 44: ......

Page 46: ...WISCONSIN MOTOR CORPORATION MILWAUKEE WISCONSIN 532466 PRINTED IN U S A...