Electrical

&

Inst

allation

requirement

s

ELECTRICAL REQUIREMENTS

Important:

Observe all governing codes and ordinances.

It is the customers responsibility:

To contact a qualified electrical installer.

To assure that the electrical installation is adequate and in conformance with National Electrical Code, ANSI/NFPA 70

latest edition*, or CSA Standards C22.1-94, Canadian Electrical Code, Part 1 and C22.2 No.0-M91 - latest edition**

and all local codes and ordinances.

If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the

ground path is adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are not sure range hood is properly grounded.

Do not have a fuse in the neutral or ground circuit.

IMPORTANT:

Save Installation Instructions for electrical inspectors use.

The range hood must be connected with copper wire only.

The range hood should be connected directly to the fused disconnect (or circuit breaker) box through metal electrical

conduit.

Wire sizes must conform to the requirements of the National Electrical Code ANSI/NFPA 70 latest edition*, or CSA

Standards C22.1-94, Canadian Electrical Code Part 1 and C22.2 No. 0-M91 - latest edition** and all local codes and

ordinances.

A U.L.- or C.S.A.-listed conduit connector must be provided at each end of the power supply conduit (at the range hood

and at the junction box).

Copies of the standards listed may be obtained from:

* National Fire Protection Association Batterymarch Park Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley Road Cleveland, Ohio 44131-5575

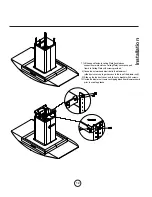

BEFORE INSTALLING THE HOOD

1.

For the most efficient air flow exhaust, use a straight run or as few elbows as possible.

CAUTION:

Vent unit to outside of building, only.

2.

Almost two people are necessary for installation.

3.

The hood is fitted with Screws and Drywall Anchors suitable for most surfaces, consult a Qualified Installer, check if

they perfectly fit with your cabinet/wall.

4.

Do not use flex ducting.

5.

COLD WEATHER installations should have an additional backdraft damper installed to minimize backward cold air

flow and a nonmetallic thermal break to minimize conduction of outside temperatures as part of the ductwork. The

damper should be on the cold air side of the thermal break.

The break should be as close as possible to where the ducting enters the heated portion of the house.

6.

Make up air: Local building codes may require the use of Make-Up Air Systems when using Ducted Ventilation

Systems greater than specified CFM of air movement.

The specified CFM varies from locale to locale. Consult your HVAC professional for specific requirements in your area.

www.windcrestcnp.com

5

Summary of Contents for PFA36SCG

Page 1: ...OCT06 0101 PFA42SCG PFA36SCG www windcrestcnp com By CNP INDUSTRIES INC ...

Page 2: ......

Page 59: ......

Page 60: ......