12

60706-229/G

cable (ground) from the engine generator assembly. All

connections must be clean and tight. Check the electrolyte

(fluid) in the battery periodically to be sure it is above the

plates. Never allow the battery to remain in a discharge

condition.

CAUTION: EQUIPMENT DAMAGE

NEVER JUMP START these units. Doing so will destroy

the engine control module, rendering the unit non-

operational. Remove and fully recharge the battery before

attempting to start.

CONNECTING BATTERY CHARGER

A two-stage battery tender is provided on all PSS series

generators. This battery tender charges at a rate of 750 mA

until the battery is fully charged and then automatically

switches to a 13.2 VDC float charger. The charger has an

indicator light on it. Red indicates it is charging, and green

indicates it is in storage mode (float charge). This charger is

mounted on the generator set which is located behind an

access cover in the rear of the unit.

The battery tender receptacle is to be powered by a GFCI

circuit and installed in accordance with the United States

National Electric Code. These AC wires can be run in the

same conduit as the other AC leads from the generator. It

is suggested that this circuit be fused for 15 Amps. Terminal

block connections have been provided in the customer

connection area of the engine-generator set. See following

diagram.

CUSTOMER CONNECTION AREA

TORQUE SCREWS TO

9.6 IN LBS. 14 TO 16

AWG COPPER WITH LUGS

CUSTOMER TO CONNECT TO

120 VOLT UTILITY LINE TO

POWER BATTERY TENDER

AND OPTIONAL ENGINE

HEATER

CUSTOMER GENERATOR

OUTPUT CONNECTIONS TO

EMERGENCY TRANSFER

SWITCH

TORQUE TO 16 IN LBS

RATED FOR 4 TO 10 AWG

COPPER - 85 AMPS

EMERGENCY STOP CONTACTS PROVIDED

FOR REMOTE EMERGENCY STOP SWITCH

UNIT WILL NOT RUN IF JUMPER IS REMOVED

2-WIRE CONNECTOR

THIS IS PLUGGED INTO

MATCHING CONNECTOR

BELOW THE CONTROL MODULE

CUSTOMER DC CONNECTIONS

TO 2-WIRE AUTOMATIC

TRANSFER SWITCH 1 & 22/23

CUSTOMER EARTH

GROUND CONNECTED HERE

AS REQUIRED

ENGINE CONTROL

MODULE ASSEMBLY

BATTERY

TENDER

START & FUEL

RELAYS

NOTICE:

The battery tender is not intended to recharge a battery

which has become completely discharged. It is designed to

produce enough current to recharge a slightly low battery

and maintain a fully charged battery.

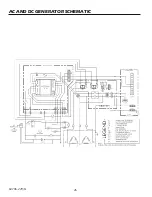

Summary of Contents for PSS20B2W/A

Page 19: ...19 60706 229 G...

Page 24: ...24 60706 229 G OUTLINE DRAWING...

Page 25: ...25 60706 229 G PAD LAYOUT 60706 229 23 12270 01 60706 229 ET A ENGINE GENERATOR SET PAD LAYOUT...

Page 26: ...26 60706 229 G AC AND DC GENERATOR SCHEMATIC...

Page 27: ...27 60706 229 G AC WIRING SCHEMATIC PSS20 3 A PSS20 17 A PSS20 18 A PSS20 4 A...