en

20

Installation and operating instructions • Wilo-Rexa FIT-S • Ed.01/2022-03

•

Mechanical screw locking device

Always re-apply the screw locking device!

Thread-locking fluid

Medium-strength thread-locking fluid (e.g. Loctite 243) is used for

the liquid screw locking compound. This threadlocker can be

loosened with increased force. If the thread-locking fluid cannot

be loosened, then the compound must be heated to approx. 300 °C

(572 °F). Clean the components thoroughly after dismantling.

Mechanical screw locking device

The mechanical screw locking device consists of two Nord-Lock

wedge lock washers. The screw connection is secured by the

clamping force. The Nord-Lock screw locking device must only be

used on bolts with strength class 10.9 which have been coated

with Geomet.

The use of stainless screws is prohibited!

9.6.2

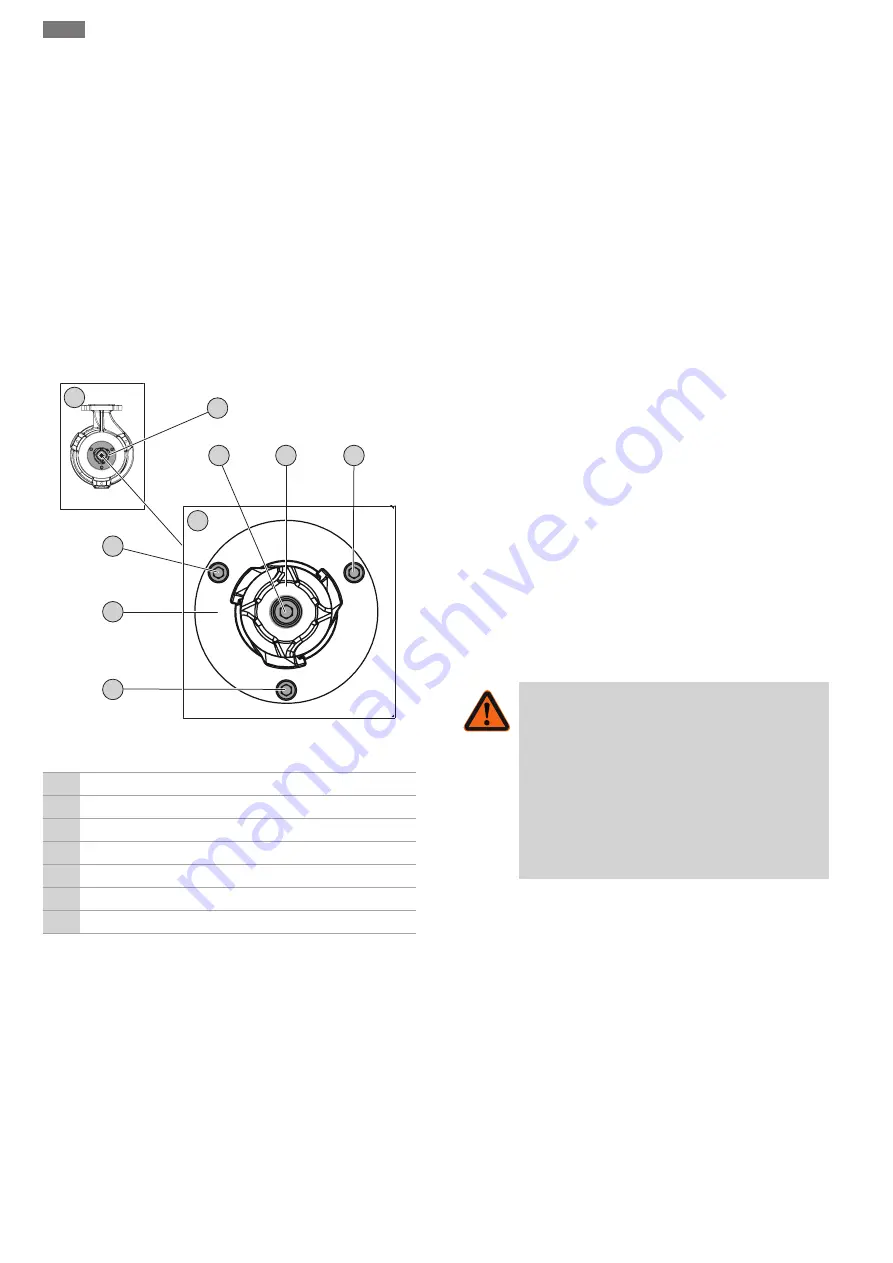

Replace macerator

A

B

1

2

3

4

4

4

5

Fig. 9:

Replacing the macerator

A

Overview: View from below

B

Detail view: Macerator with fixation

1

Macerator

2

Cutting plate

3

Cutting head

4

Cutting plate fixation M6

5

Cutting head fixation M8

✓

Wear protective glove!

✓

Pump cleaned and disinfected if necessary.

✓

Hexagon socket with T-handle, sizes 5 and 6.

✓

Torque wrench.

✓

Wedge (width: approx. 10 ... 15 mm) made of hardwood or

plastic to secure the cutting head.

CAUTION! Do not use a metal wedge! A metal wedge can

damage the blades.

✓

Liquid thread-locking fluid, medium strength (e.g. Loctite

243).

1.

Secure the cutting head: Insert wedge between cutting head

and cutting plate.

2.

Loosen and remove fastening screw on cutting head.

3.

Remove wedge.

4.

Pull off cutting head.

WARNING! Cut injury! Do not touch

cutting head on cutting blade!

5.

Fit new cutting head.

6.

Wet fastening screw with thread-locking fluid and screw it

into cutting head. Tighten the fastening screw hand-tight.

7.

Secure the cutting head: Insert wedge between cutting head

and cutting plate.

CAUTION! Tighten fastening screw hand-tight before in-

serting wedge! The wedge can displace the cutting head.

8.

Tighten fastening screw on cutting head to 18.5 Nm (13.5 ft

lb).

9.

Remove wedge.

10. Loosen and unscrew cutting plate fastening screws.

11. Carefully lever out cutting plate with wedge.

12. Remove cutting plate.

WARNING! Cut injury! Do not touch

cutting plate on blade!

13. Insert new cutting plate.

14. Wet cutting plate fastening screws with thread-locking fluid

and screw in.

15. Tighten cutting plate fastening screws crosswise to 7.5 Nm

(5.5 ft lb).

▶

Macerator changed.

NOTICE! Observe drying time! Allow the thread-locking fluid to

dry before using the pump.

10

Faults, causes and remedies

WARNING

Risk of injury from rotating components!

No persons are allowed to be present in the working

area of the pump. There is a risk of injury!

• Demarcate and cordon off the working area.

• If there are no persons in the working area, activ-

ate the pump.

• If persons enter the working area, switch off the

pump immediately.

Fault: Pump does not start

1.

Electricity supply interrupted or short-circuit/earth fault in the

cable or motor winding.

⇒

Have the connection and motor checked by a qualified

electrician and replace if necessary.

2.

Tripping of fuses, of the motor protection switch or the mon-

itoring device

⇒

Have the connection and the monitoring device checked by

a qualified electrician and change it if necessary.

⇒

Have the motor protection switches and fuses installed and

adjusted according to the technical specifications by a

qualified electrician and reset monitoring device.

⇒

Check the impeller to make sure that it runs smoothly,

clean the hydraulics if necessary.