GWS-090E

Gas-Fired Water Boiler –

Boiler Manual

10

Part Number 550-110-737/1108

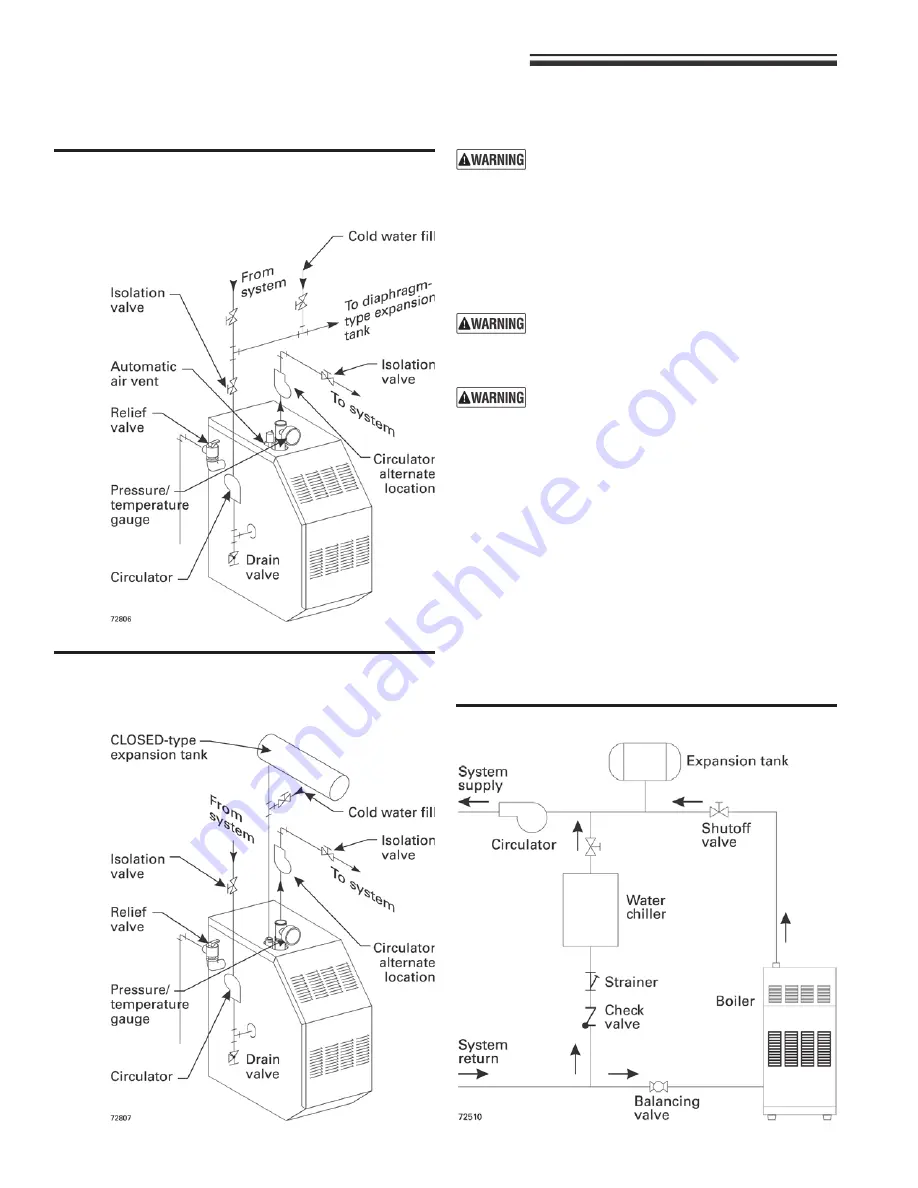

Figure 3

Diaphragm- or bladder-type expansion tank:

Piping to single-zone system using

diaphragm-type or bladder-type expansion

tank. See Table 5, page 9, for piping sizes.

Figure 4

Closed-type expansion tank: Piping to single-

zone system using closed-type expansion

tank. See Table 5, page 9, for piping sizes.

Figure 5

Piping refrigeration systems

3 Install water piping

continued

Water piping — refrigeration systems

Prevent chilled water from entering boiler

Install boiler so that chilled medium is piped in parallel with the

heating boiler. Use appropriate valves to prevent chilled medium

from entering boiler. See Figure 5 for typical installation of balanc-

ing valve and check valve.

Install boiler so that chilled medium is piped in par-

allel with heating boiler. Use appropriate valves to

prevent chilled medium from entering boiler. Consult

I=B=R Installation and Piping Guides.

If boiler is connected to heating coils located in

air handling units where they can be exposed to

refrigerated air, use flow control valves or other au-

tomatic means to prevent gravity circulation during

cooling cycle. Circulation of cold water through the

boiler could result in damage to the heat exchanger,

causing possible severe personal injury, death or

substantial property damage.

If system includes radiant heating circuits, provide

piping and controls to regulate the temperature sup-

plying the radiant circuits. Failure to comply could

result in substantial property damage.

Use Figure 3 or Figure 4 only for systems designed

for return water at least 130 °F. For systems with

low return water temperature possible, such as con-

verted gravity systems and radiant heating systems,

install bypass piping (see page 11) to protect boiler

against condensation. Failure to prevent low return

water temperature to the boiler could cause corro-

sion of the boiler sections or burners, resulting in

severe personal injury, death or substantial property

damage.