www.wika.com

2

3. VALVES IDENTIFICATIONS

We recommend checking, before commissioning, that

the conditions of use are in compliance with the design

specification of the valve.

Valves features can be read on the tag plate attached to

the

valve

body.

Valves identifications included:

-

Part number

-

Inlet & outlet dimensions and class

-

Tag number

-

Heat codes

-

Drain size

-

Specification applied

-

Lot number

4. HANDLING AND STORAGE

Valves shall be stored in a dry and clean place.

Condensation shall be avoided through suitable warming

and ventilation system.

Prior to storage, inspect the valve for shipping damage.

Keep all protective packaging, flange covers and end

caps attached to the valves during storage.

During storage valves shall be kept in close position to

avoid introduction of foreign bodies.

Carbon steel valves have an oil finish to retard rusting

during storage: it is not a substitute for paint or other

means of protective coating to be applied to the valve

once installed.

Stainless steel valves have their natural finish and do not

require additional protection once installed.

Valves shall be handled by use of lifting lugs or other

suitable lifting devices.

It is suggested not to lift the valves by means of valve

handles.

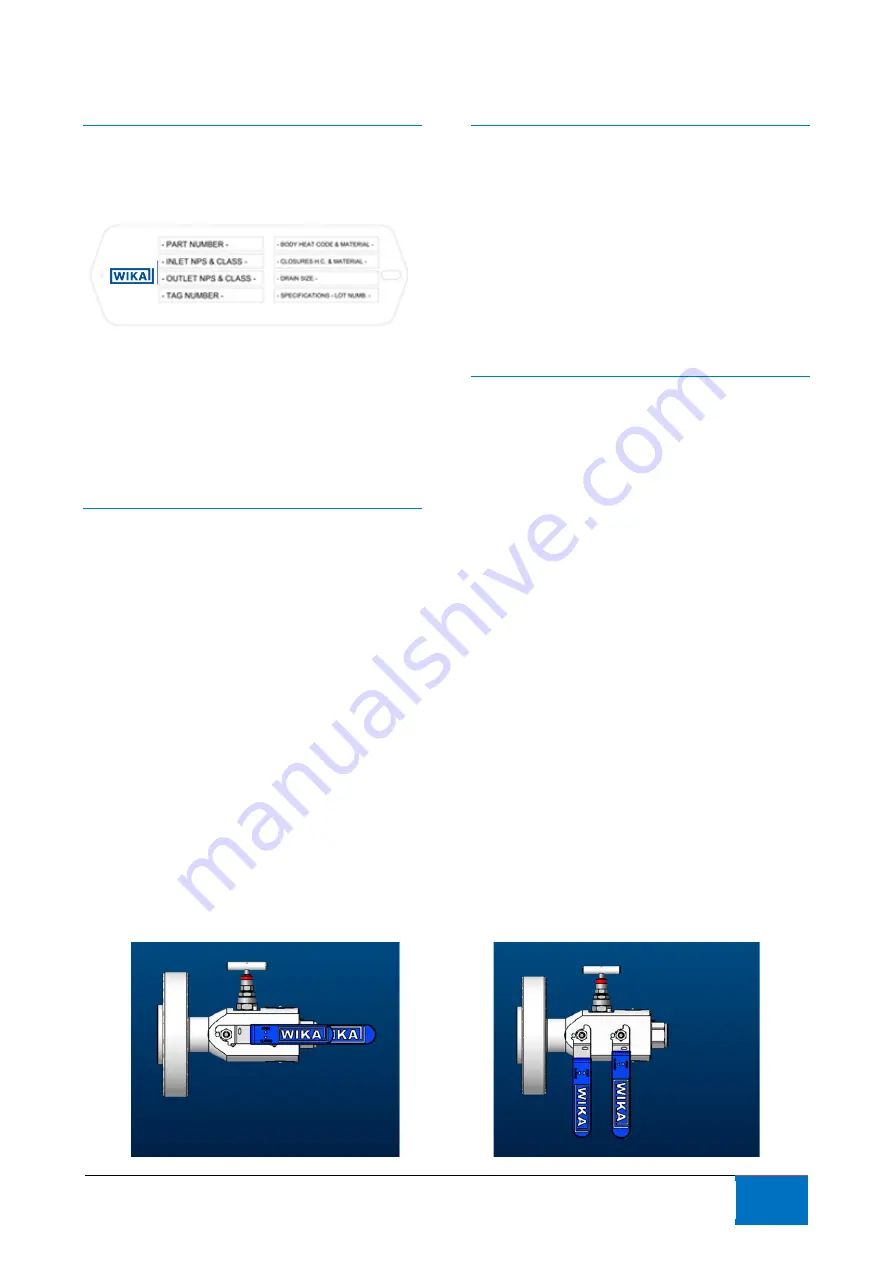

5. OPERATING INSTRUCTIONS

On manual operated valves, the valve operation is done

by turning the valve handle 90° clockwise to open

(handle is parallel to flow line), and 90° counter clockwise

to close (handle is perpendicular to flow line).

The bleed line should be in closed position while flow line

is in open position, and open when flow line is in closed

position. To open the bleed valve, turn counter clockwise

the T bar up to the limit. To close turn clockwise the T

bar.

Before starting to open the bleed valve is suggested to

remove the plug on the bleed line if any.

6. INSTALLATION

Monoblock instrumentation valves are potentially

bidirectional so they do not have preferential flow

direction.

Just before installation unpack the valve and remove the

flange and closure fitting protection: ensure that no

packing material are in the flow passages or attached to

the body.

Check for damage and internal and external corrosion if

any.

Inspect the functionality of the valve opening and close

few times both flow line and bleed line.

Balls shall be in open position during the installation to

avoid their damage.

Make sure that flange faces and threads ends are free

from damage, rust, dust or foreign bodies.

It is suggest to clean flanged pipeline connection before

the installation of the valve (flush with nitrogen or other

inert gas) and to remove foreign bodies or dirt from the

internal of the pipes.

If welding operations are required ensure that

temperature do not exceed 150°C. We recommend to

keep the ball in open position.

Gaskets, flange bolts, bolts torque value, sealants,

adapters and tube fittings are responsibility of the

customer.

VALVE OPEN

VALVE CLOSED