Operation manual

IM 240-i

Seite 13

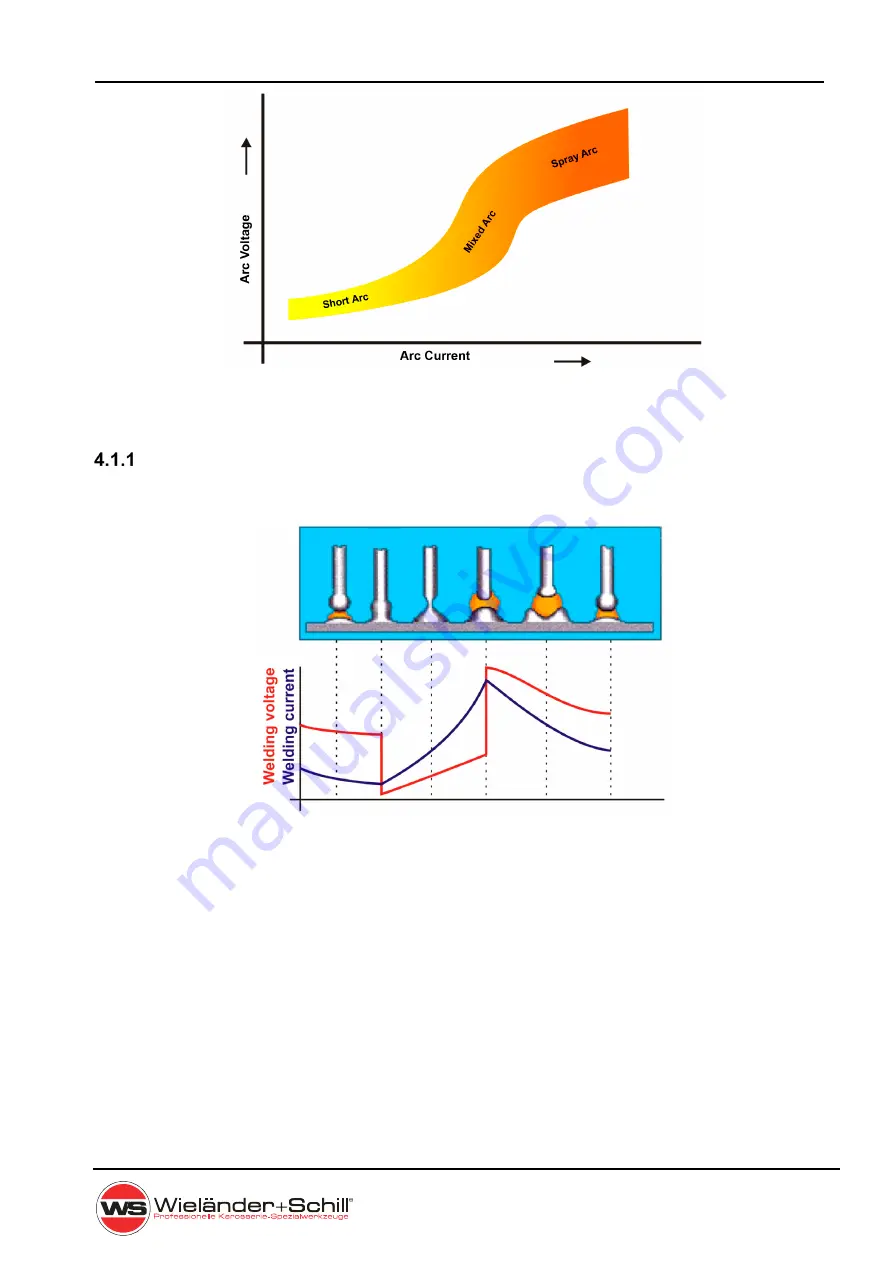

Arc ranges for 1.0mm Fe G3Si wire

Short Arc

The short arc occurs in the

lower power range

, at lower current intensities and

arc voltages.

Short arc transfer time

The arc length changes cyclically. Thus, working point shifts of welding current and welding

voltage are connected. In the phase of droplet detachment, by approaching the droplet to

the melt, the arc flash voltage decreases until the droplet passes into the molten bath. There

is a short circuit, the current increases according to the inductance of the welding circuit up

to the maximum short-circuit current. The current increase rate of the current source

determines the type of droplet separation significantly. After re-ignition of the arc, the voltage

increases suddenly. The welding current drops again and adjusts itself according to the

position of the arc operating point on the current source characteristic. The course of the

instantaneous welding current is essentially determined by the dynamic properties of the

welding current source. In modern welding power sources, these properties are generated

selectively by means of control and regulation. During the drop short, the measurable

voltage does not completely collapse, as the heated free wire length has a distinctively

dynamically changing resistance. This process is repeated between 20 to 100 times per

second.