Snow Master Vario Flex 3370

11 Maintenance

02 | 2019

3370 99 01 – 003

55

11.4.1.

General safety information for the hydraulic system

The hydraulic system is not approved for the use of BIO oils.

Only trained personnel are permitted to work on the hydraulic system!

High-pressure fluids which leak under pressure can penetrate the skin causing serious injury.

If you suspect that a pressure system may be damaged, shut down and secure the machine immediately and then

contact a qualified specialist workshop.

Never attempt to trace the source of leaks with your bare hands. Even just a pin hole can cause serious personal

injuries.

Use suitable materials when searching for leaks. (for example, a piece of cardboard)

Keep your body and face well away from leaks.

If a fluid penetrates the skin, it must be removed immediately by a doctor who is familiar with such injuries. Otherwise

serious infections may result.

Doctors unfamiliar with this type of injury should reference a knowledgeable medical source.

Prior to recommissioning, check the leak-tightness of the hydraulic system!

According to the manufacturer's specifications, the replacement period for hydraulic lines is 6 years.

11.4.2.

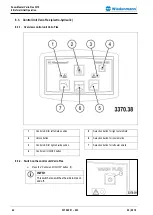

Hydraulic connection – Vario Flex electrohydraulic

Hydraulic connection for left outer shield

1

Hydraulic cylinder for left outer shield

2

Control block

3

Left pressure relief valve

4

Non-return valve

A3 Hydraulic line V1 at control block A3 (1000 mm)

B3 Hydraulic line V2 at control block B3 (1000 mm)

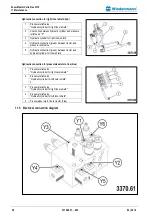

Hydraulic wiring diagram for right outer shield

1

Hydraulic cylinder for right outer shield

2

Control block

3

Right pressure relief valve

4

Non-return valve

A4 Hydraulic line V2 at control block A4

B4 Hydraulic line V1 at control block B3