10

18. ROUTINE SERVICING

To ensure continued safe and efficient operation of the appliance it is recommended that it is checked and serviced at

regular intervals. The frequency of servicing will depend upon the particular installation conditions and usage but in

general once a year should be regarded as a minimum, even if only occasional usage has occurred. It is a legal

requirement that any service work MUST be carried out by a registered engineer.

Before leaving the factory the heater is pre-set in accordance with the information on the data plate. No adjustment is

necessary and under no circumstances should any of the seals be broken. This includes the removal of the front case

which can only be done by a qualified technician.

19. CLEANING

In addition to routine servicing carried out by a qualified technician it is recommended that the outer case be cleaned

periodically. This should be done with a soft dry cloth. Care should be taken not to damage the LCD control panel.

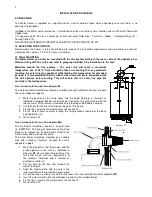

Periodically the flue terminal should be checked to ensure that it is clean and free of debris. A visual inspection is

recommended and if debris is noticed the appliance should be turned off and the terminal dismantled and cleaned. When

replacing the terminal ensure that it is correctly fitted – refer to section 12 of this manual.

20. SAFETY

It is essential that these instructions are strictly followed for the safe and economical operation of this appliance.

The appliance is a fan-assisted room sealed gas water heater and therefore the flue terminal MUST NOT BE

OBSTRUCTED under any circumstances. If it is damaged, turn off the appliance and consult your installer, or service

engineer. If it is known or suspected that a fault exists on the appliance it MUST NOT be used until the fault has been

rectified by a competent person.

21. PRECAUTIONS AGAINST FREEZING DURING WINTER STORAGE

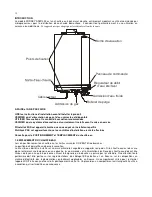

During cold periods and if the water heater is situated in a place liable to freeze, the water must be completely drained

from the water heater as follows:

1. Turn off the cold water Supply.

2. Open all the hot water outlet taps on the installation.

3. Release the drain plugs fitted at the lowest point of the pipe work.

4. Open the bleed valve on the side of the water inlet fitting a few turns to allow air into the system.

NOTE: There is no drain plug fitted to the hot water heater side of the water heater.

When the operation is finished, close the hot water outlet taps and replace the drain plug and tighten the bleed valve on

the side of the water inlet fitting.

To put the water heater back into service, open the cold water supply.

NOTE: In a Caravan Holiday Home installation there may be a drain cock on the cold inlet under the van directly

below the water heater which may be used.

22. COMMISIONING

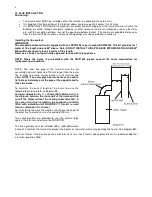

Before commissioning, ensure that the whole gas installation is purged and tested for soundness. Always ensure that

connections made to the appliance for gas type, gas pressure and water pressure are in accordance with the appliance

data plate.

23. POST INSTALLATION CHECKS

GAS CIRCUIT

Turn on the gas supply and check for leaks downstream of the isolation cock using leak detector spray.

WATER CIRCUIT

Turn on the water supply and check for leaks.

INITIAL OPERATION

Operate the heater as per the instructions in section 14 of this manual.

FINAL CHECKS

Re-light and test for gas soundness

Carry out an operating gas pressure test to ensure maximum potential performance.