Aquatronic 4 Ultra electric shower

W-001-A

WARNING!

Before normal operation of the

shower, it is essential the following

commissioning procedure is completed

correctly.

At this stage, temporarily fit the cover in order to

carry out the commissioning procedure.

The first operation of the shower is intended to

flush out any remaining unit debris and to make

sure the heater unit contains water before the

elements are switched on.

Refit the trimplate.

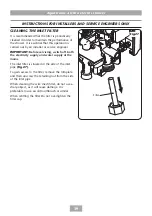

Turn the valve spindle fully clockwise until the

spindle hits the ‘stop’

(fig.)

. DO NOT force

the spindle.

Turn the temperature control on the cover to the

minimum flow position

(fig.)

.

Offer the cover to the unit.

I-004-A

IMPORTANT!

Do not connect the 10-way ribbon

cable at this stage.

Carefully locate the cover onto the backplate

and make sure the wires are not trapped.

Guide the cover into position so that the control

spindle locates correctly (minor adjustment may

be necessary to align the control and spindle).

Should any difficulty arise, recheck the points

above.

While applying slight pressure to the front

cover, secure in position with the three retaining

screws.

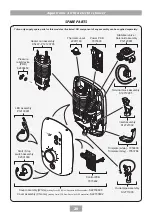

Fit the flexible hose to the shower outlet making

sure the outlet of the hose is directed to waste.

Check the supplied sealing washer is in place.

Do NoT attach the showerhead at this stage.

Before turning on the electric and mains

water supplies to the shower, make sure the

temperature control is rotated fully clockwise to

‘HOT’, the minimum flow position

(fig.)

.

note:

Failure to rotate the valve spindle fully

clockwise may cause the PRD to operate.

Commissioning

COMMISSIONING

T00390

>POM-GF30<

Valve

spindle

Fig.

Fig.

Temperature control set

at minimum flow setting