WHITEHALL MANUFACTURING

• P.O. BOX 3527 • City of Industry, CA 91744-0527 U.S.A

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

8

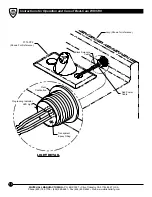

Instructions for Operation and Care of Best-Care WH3740

Assemble waste piping using teflon tape on all threaded

5

connections and make up waste connections to 1-1/2" P-trap.

WASTE ASSEMBLY

HINT: Teflon tape is recommended on all threaded waste and

supply connections.

3

1

2

"

REF.

4

5

8

" REF.

4

5

8

" REF.

Rubber Gasket

Overflow Adapter

Red Flat Fiber Gasket

1-1/2" - 16 UNI Rough Chrome Brass Nut

1-1/4" - 27 UNI Close Ell w/ 3/8" NPTI Clean-Out

Plug

Waste Outlet Connection

Strainer Flange

11

10

9

8

7

6

5

Strainer w/ 1-1/2" - 16 UNE Threads

4

3/8" O.D. x 3/8" NPT Female Connection

2

Overflow Insert

1

1

2

4

5

6

3/8" O.D. x 3/8" NPT Male Connection

7

5

8

9

10

11

3

3/8" O.D. Overflow Tube

3

NOTE: Waste assembly may require field cutting and fitting by the

installer.

Install strainer to basin using plumbers putty

4

on underside of grid strainer flange. Insert the

Overflow Insert through the Overflow Hole and

tighten to 3/8” O.D. Elbow Adapter. From

beneath basin, assemble rubber gaskets,

overflow adapter, fiber gasket and jam nut as

shown to strainer and tighten securely. Add

close elbow to strainer assembly as indicated.