11

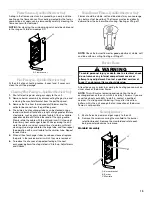

Electrical Power Routed Through Bottom of Unit

NOTE: Junction box location shown is optional and is for

illustration purposes only.

Unit Voltage

The unit transformer is factory-connected for 230V operation. If

the unit is to operate on 208V, reconnect the transformer primary

lead as shown on the unit wiring diagram.

Heat Anticipator Setting

The heat anticipator is to be set by measuring the load

(amperage) at the R circuit. Follow the instructions provided by

the thermostat for more details.

Typical Thermostat and Unit 24V Wiring Hookup

CIRCULATING AIR AND FILTERS

Airflow Conversion

Units can easily be converted from horizontal to down-discharge

airflow delivery. In down-discharge or high-static installations, the

installer should measure the total external static and review the

blower performance charts before performing the installation. In

some installations, it will be necessary to change the blower

speed to provide proper airflow.

Duct Cover Installations—Down-Discharge

Remove the panels for down-discharge duct applications

Down-Discharge Applications

Cut insulation around bottom openings and remove panels from

the bottom of the unit, saving the screws holding the panels in

place.

NOTE: Single-phase models require installation of horizontal

duct kit #20464501PDGK (medium chassis) and

#20464502PDGK (large chassis).

Ductwork

Duct systems and register sizes must be properly designed for

the C.F.M. and external static pressure rating of the unit.

Ductwork should be designed in accordance with the

recommended methods of Air Conditioning Contractors of

America Manual D (Residential) or Manual Q (Commercial).

All ductwork exposed to the outdoors must include a

weatherproof barrier and adequate insulation. A duct system

should be installed in accordance with Standards of the National

Board of Fire Underwriters for the Installation of Air Conditioning,

Warm Air Heating and Ventilating Systems. Pamphlets No. 90A

and 90B.

The supply duct from the unit through a wall may be installed

without clearance. However, minimum unit clearances must be

maintained. The supply duct should be provided with an access

panel large enough to inspect the air chamber downstream of the

heat exchanger. A cover should be tightly attached to prevent air

leaks.

For duct flange dimensions on the unit, refer to the Unit

Dimension illustration in the Appendix.

For down-discharge applications, the ductwork should be

attached to the roof curb prior to installing the unit. Ductwork

dimensions are shown in the roof curb installation manual.

If desired, supply and return duct connections to the unit may be

made with flexible connections to reduce possible unit operating

sound transmission.

G

Y

W

R

R

W

Y

G

From

Unit

A. Supply air panel

B. Return air panel

A B