ON

11

OFF

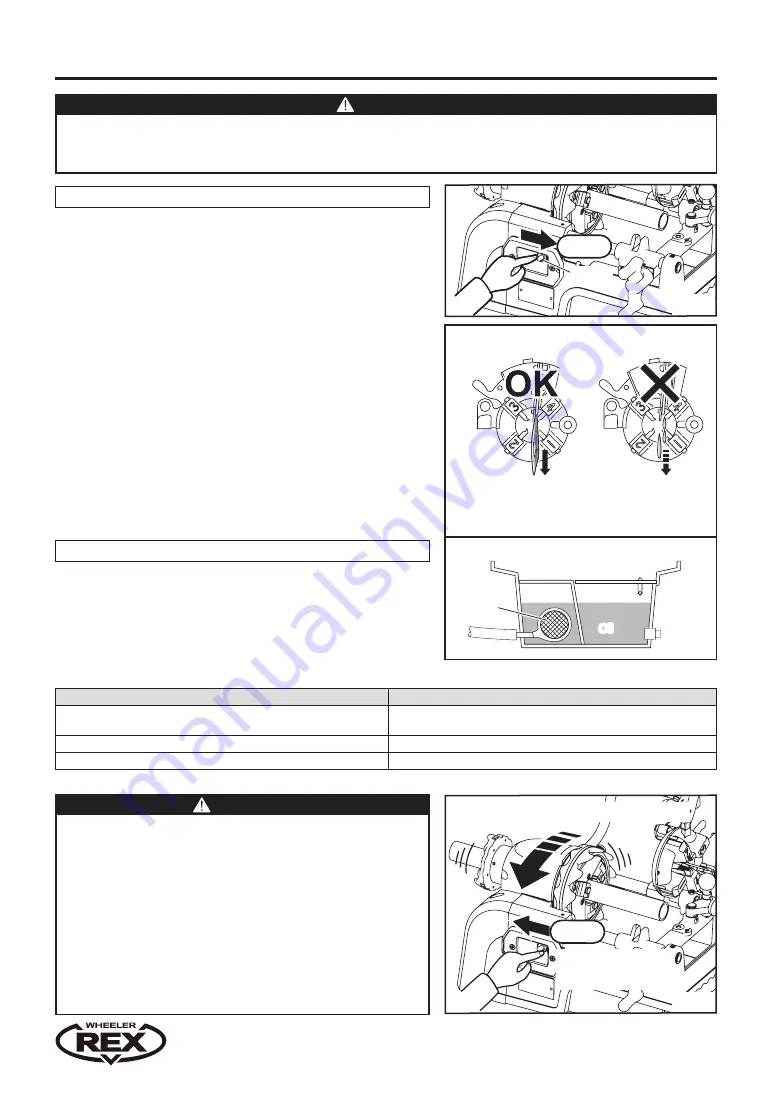

Fig. 21-1

Fig. 22

GETTING READY / OPERATION GUIDE

Problem

Remedy

The carbon brushes are worn out.

Replace with new ones according to the procedures on

Pg. 17, Fig. 40.

When the motor becomes overheated from continuous use

Wait for the motor to cool down and start again.

When an oxide fi lm is generated in the motor

Allow the motor to rotate for about 10 minutes with no load.

Table 3

Fig. 21-2

Motor with built-in braking system

WARNING

Carry out the following checks before starting to cut or thread pipes.

Should any problems arise, refer to "Troubleshooting" at the end of this manual and follow the appropriate instructions.

Continuing to use the machine when a problem has arisen can lead to accident or injury.

9. Checks before starting

(1) Turn on the machine to set the main shaft in motion. (Fig. 20)

- Check there are no abnormal sounds or odours coming from the motor.

- Check the pipe you installed does not vibrate abnormally. If it

does, install it again.

(2) Check that cutting oil fl ows as it should from the die head. (Fig. 21-1)

Confi rm that there is at least 1 liter of cutting oil in the tank. (tank

capacity:1.5 L)

When the volume of oil emitted from the die head is reduced, check

that the amount of cutting oil in the tank is at least suffi cient to cover

and hide the strainer. (Fig. 21-2) Replenish the oil as required.

* If the volume of oil fl owing from the die head remains low even

after the oil has been added, please contact your distributor or

WHEELER-REX.

(3) Allow the machine to rotate without any load for several minutes.

- Check the motor does not become abnormally hot, etc.

(4) Turn the machine off and allow it to stop rotating.

- Check there are no abnormal sounds or odours coming from

the motor. The unit uses a motor equipped with a built-in braking

system for improved safety. Make sure you read and understand

the points below relating to the use and performance of the system.

10. Motor with braking system

(Fig. 22)

The braking system in the motor is designed to minimise idling

after turning the machine off, and to prevent unexpected accidents

and injuries. The motor can stop within fewer rotations than

conventional ones. However, under certain conditions the braking

system may not engage correctly or it may become ineffective.

Read the following cautions carefully to ensure correct use.

Please note that the effectiveness of the brake will be diminished in the following cases.

If the brake does not work even under such circumstances, contact your distributor or WHEELER-REX.

WARNING

1. Make sure the braking system is working before using the machine.

- Although this machine is equipped with both a braking system

and a safety switch, the brake may not work or it may become

ineffective depending on conditions. Check the effectiveness

of the brake before use, and wait till the motor comes to a

complete stop before moving on to the next operation.

2. Be sure to use REX carbon brushes.

- Using other brushes may damage the motor or the machine itself,

or the brake may not be applied.

3. Do not use the machine in rain, humid or damp places, or places

where moisture can easily get into the machine.

- If stored for long periods in a humid place, an oxide fi lm may form

on the motor, and the brake may not be engaged. Store in a place

with low humidity.

brake is effective

as OFF position

Oil

Strainer

Checking the amount of thread cutting oil /Oil tank

Con

fi

rming the amount of thread cutting oil

/ Die head

Appropriate amount of oil

flows smoothly without

interruption

Small volumes of oil

containing air bubbles

produced intermittently

come out

Fig. 20

Switch