WHL-016 Rev. 4.14.16

55

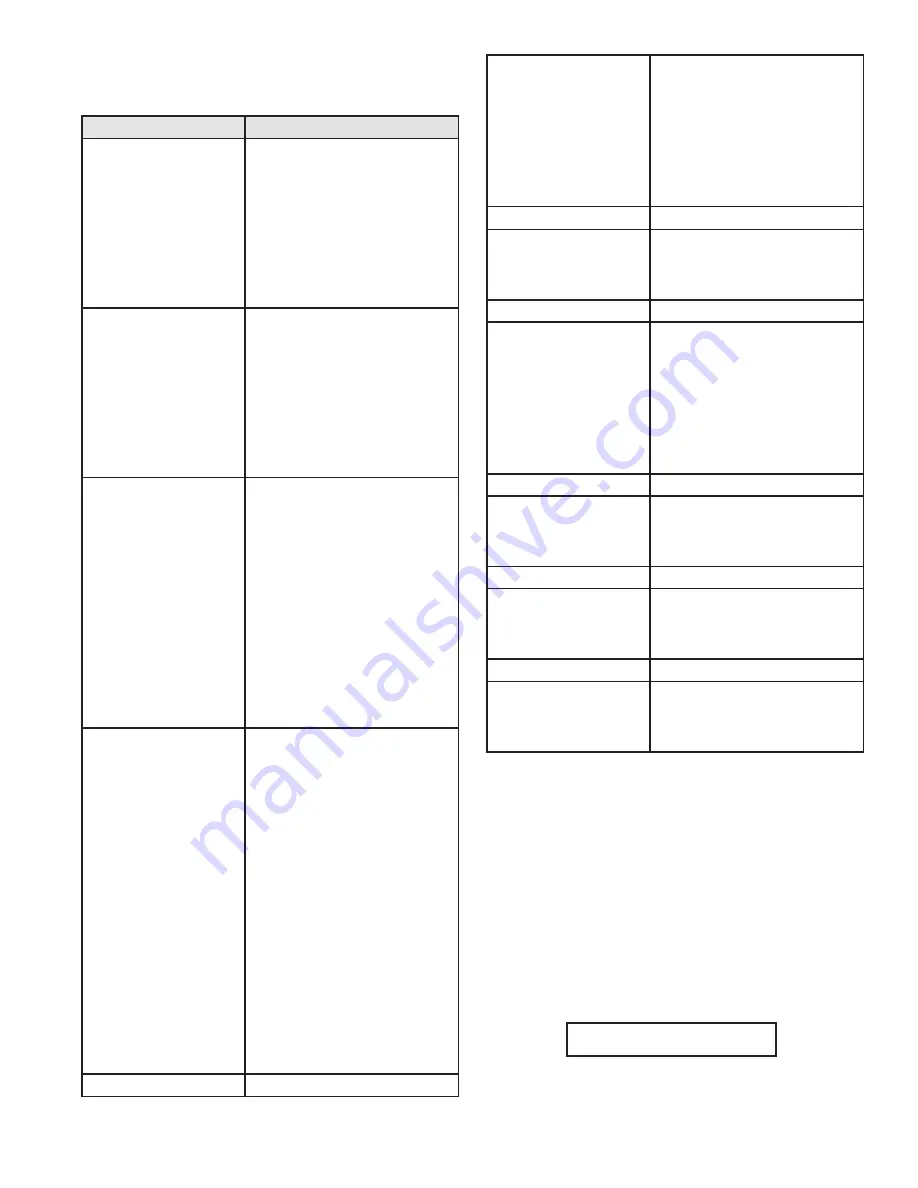

Screen

Description

CASCADE MASTER READY

SYS PUMP OFF

This screen displays when the boiler

is configured as a Cascade Master

and the system is ready to accept

a demand for heat. The second line

indicates the cascade system pump

output status. This screen alternates

with the default screen every 5

seconds or can be accessed by

pressing the

<

key from the default

screen.

CASCADE NO FOLLOWER

SYS PUMP OFF

This screen displays when the boiler

is configured as a Master Boiler and

there are no connected follower

boilers, or the follower boilers are not

powered. The second line indicates

cascade system pump output status.

This screen alternates with the

default screen every 5 seconds or

can be accessed by pressing the

<

key from the default screen.

CASCADE NO SENSOR

SYS PUMP OFF

This screen displays when the boiler

is configured as a Master Boiler and

there is no system temperature

sensor connected or the system

sensor is defective. The cascade

system will still function in this

situation with reduced efficiency.

All boilers will run simultaneously

rather than in a staged fashion.

The second line indicates cascade

system pump output status. This

screen will alternate with the default

screen every 5 seconds or can be

accessed by pressing the

<

key from

the default screen.

CASCADE TT 0123 567

SYS PUMP ON 12:47P

This screen displays information

about cascade status. The TT in

the center of the top line shows

that cascade demand is coming

from the TT contact being closed.

You may also see DHW if the

demand is from a DHW sensor, or

0-10 if the demand is from a 0-10

volt input. The following numbers

show which boiler addresses are

currently communicating to the

master. If a boiler address is not

used or communicating, the number

will not display. In the example to

the left, boiler address #4 is not

communicating. When a boiler in the

system is firing, its address number

will alternate with a ‘.’ to signify it

is firing. The bottom line shows the

status of the system pump output

contacts.

Press v once.

CASCADE PWR 100%

PRESENT 01234567

This screen displays overall cascade

power output. The range of this

value is the number of boilers

communicating with the Master x

100. For example, if 8 boilers are

connected and firing, the maximum

cascade power is 800%. The second

line shows which boiler addresses

are communicating with the Master.

Press v once.

CASCADE SYST 118

o

F

CASCADE SET 190

o

F

This screen displays current system

temperature sensor reading on the

top line and the cascade system

temperature setting on the bottom.

Press v once.

BOILER 0 100%

BOILER 1 56%

This screen displays the current

cascade power demand output

on a per connected boiler basis

for boilers addressed as 0 and 1.

In the example, boiler 0 is being

commanded to fire at 100% and

boiler 1 at 56%. If this were a 2 boiler

system, the ‘CASCADE PWR’ screen

above would read 156%.

Press v once.

BOILER 2 0%

BOILER 3 0%

This screen displays the current

cascade power demand output on a

per connected boiler basis for boilers

addressed as 2 and 3.

Press v once.

BOILER 4 0%

BOILER 5 0%

This screen displays the current

cascade power demand output on a

per connected boiler basis for boilers

addressed as 4 and 5.

Press v once.

BOILER 6 0%

BOILER 7 0%

This screen displays the current

cascade power demand output on a

per connected boiler basis for boilers

addressed as 6 and 7.

Table 23 - Cascade Menu

B. Cascade Menu

This menu is accessed by pressing

<

at the default menu or

>

at

the status menu.

C. Boiler Test Mode

This function is intended to simplify gas adjustment. The

following tables include recommended combustion settings

by fuel type and boiler fan speeds. Automatic modulation does

not take place while the controller is in Test Mode. However,

the boilers will modulate down if the program set point is

reached while running in Test Mode. It is recommended to enter

Test Mode with the largest load possible to create such a heat

demand that Test Mode will not be interrupted. To enter Test

Mode press

^

and

ENTER

simultaneously.

NOTE:

The boiler will automatically exit Test Mode after 20

minutes of operation.

To leave Test Mode press

^

and

v

simultaneously.

SERVICE RUN 3400 RPM

PUMP ON 4:49P

Summary of Contents for WBC 399

Page 14: ...WHL 016 Rev 4 14 16 14 Figure 6 Boiler Dimensions NOTE All Dimensions Are Approximate 055 080 ...

Page 21: ...WHL 016 Rev 4 14 16 21 Figure 9 Piping Symbol Legend ...

Page 42: ...WHL 016 Rev 4 14 16 42 Figure 33 Internal Connection Diagram ...

Page 65: ...WHL 016 Rev 4 14 16 65 Figure 37 Combustion System Replacement Parts 55 110kBTU Models ...

Page 67: ...WHL 016 Rev 4 14 16 67 Figure 39 Combustion System Replacement Parts 155 399kBTU Models ...