6. M

AINTENANCE

& S

TORAGE

W

ESTFIELD

- G

RAIN

A

UGERS

W130 - 31’ & 36’ PTO-SD & EMD

42

30749 R0

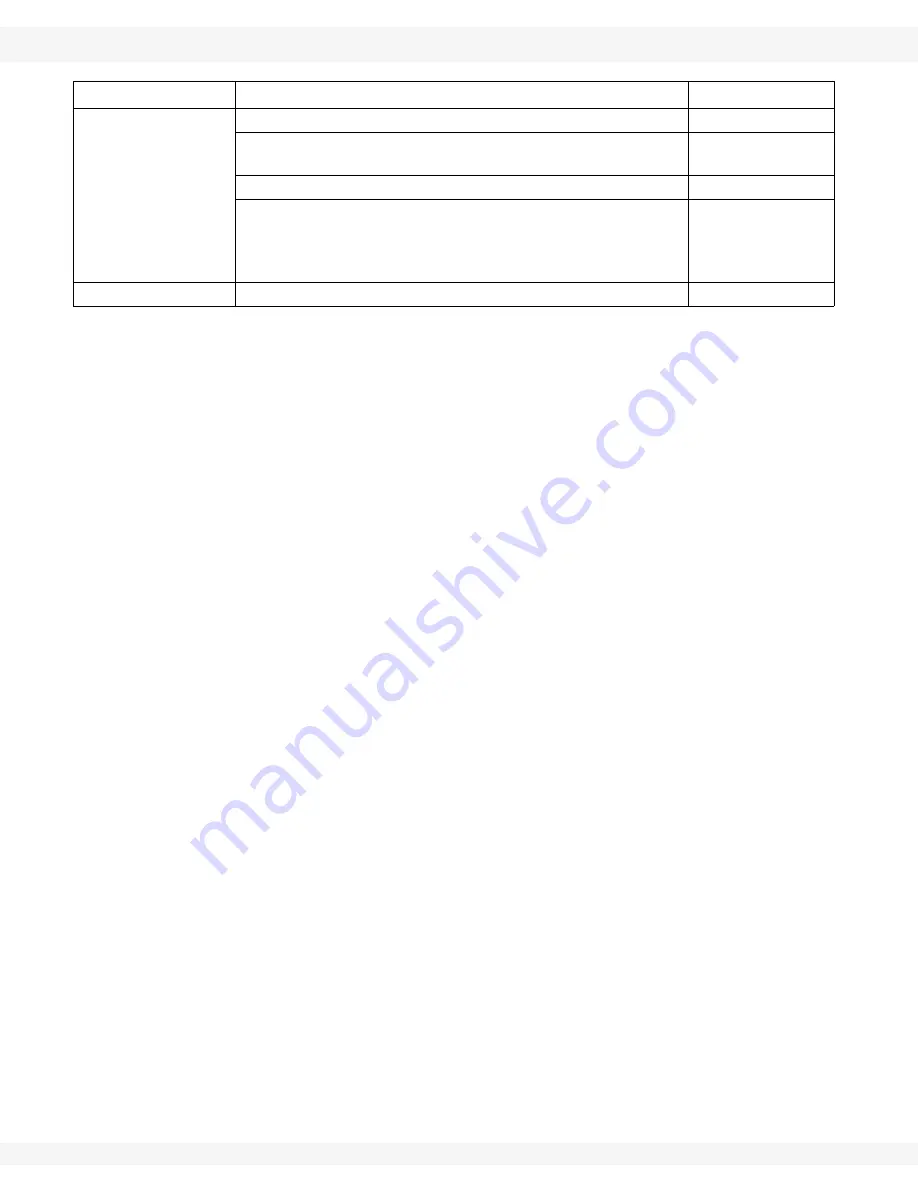

Winch

Note: Service

winch with auger in

fully lowered posi-

tion and cable

slack.

Keep a film of grease on gears.

Regularly

Oil the ratchet pawl pivot, bushings, and pinion threads.

Do not get oil or grease on brake discs.

Occasionally

Replace brake discs if less than 1/16” thick.

As required

Check for proper ratchet pawl operation.

When cranking in (clockwise) = loud clicking

When cranking out (counterclockwise) = no clicking and

ratchet pawl fully engaged into gear teeth

Regularly

Truss Cables

Adjust to keep auger tube reasonably straight.

As necessary

Area

Maintenance

Frequency

Summary of Contents for W130-31

Page 6: ...1 INTRODUCTION WESTFIELD GRAIN AUGERS W130 31 36 PTO SD EMD 6 30749 R0 ...

Page 14: ...2 SAFETY WESTFIELD GRAIN AUGERS W130 31 36 PTO SD EMD 14 30749 R0 ...

Page 30: ...3 ASSEMBLY WESTFIELD GRAIN AUGERS W130 31 36 PTO SD EMD 30 30749 R0 ...

Page 34: ...4 TRANSPORT PLACEMENT WESTFIELD GRAIN AUGERS W130 31 36 PTO SD EMD 34 30749 R0 ...

Page 40: ...5 OPERATION WESTFIELD GRAIN AUGERS W130 31 36 PTO SD EMD 40 30749 R0 ...

Page 44: ...6 MAINTENANCE STORAGE WESTFIELD GRAIN AUGERS W130 31 36 PTO SD EMD 44 30749 R0 ...