Operation and Maintenance Manual of WP13C Series Diesel Engines

Weichai Power Pursuit of Excellence

- 5 -

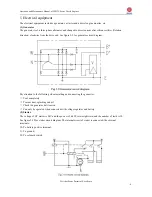

The fuel system mainly consists of the fuel delivery pump, fuel filter, high pressure fuel pump, fuel injector

and high/low pressure oil pipes. When the diesel engine is working, the fuel delivery pump absorbs diesel

fuel from the fuel tank, the fuel flows through the fuel filter, high pressure fuel pump,

enters the fuel injector for being injected into the combustion chamber, and remaining diesel fuel flows

back to the fuel tank through the fuel return pipe. (See figure 2-4).

The fuel system is a very critical component of diesel engine and is externally connected with the fuel tank

and fuel pipes, and its manufacturing and mounting quality and the fuel quality used influence the

performance and reliability of diesel engine. The user’s fuel tank shall be clean, free of rust and corrosion,

and there shall be no impurity generated by chemical reaction between materials and diesel fuel. The fuel

tank shall be equipped with a fuel drainage device to drain water and impurities in the fuel, and it is

preferable that the fuel outlet pipe of fuel tank be equipped with a valve to facilitate maintenance of

pipeline.

3.1 Fuel return

When mounting the fuel return pipe, be careful to avoid contact with high temperature parts (exhaust pipe,

turbocharger, exhaust return pipe, etc) of the diesel engine. No throttling area is allowed in the fuel return

pipe. The fuel return pipe shall not contact with sharp edges, or be bent into sharp corner, or even twisted.

Improper mounting of the fuel return pipe may cause fuel leakage to engine.