Dosing unit GRANUDOS Type Flex-CPR Touch XL,

Type Flex-Touch and Type Flex-S5

Index: 01 Change date: 11/10/2023

OI No.: BA SW 022-01 Granudos Flex Dosiereinheit EN.docx

Page 17 of 68

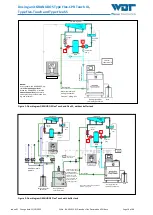

The pressure switch, installed on the pressure side of the booster pump, switches off the GRANUDOS

in the event of a pressure drop or the intake of air to prevent the booster pump from running dry.

In addition, a control switch can be connected to turn off the dosing in the event of a fault in the

swimming pool filter system, e.g., no flow in the clean water line.

In case of water-MIN and pure water contact, the dosing and the booster pump are switched off.

In case of water-MAX, the dosing is stopped and the booster pump continues to run.

A flow switch (42) is installed in the injector’s suction line (40); this is of essential importance for the

GRANUDOS’s operational safety! If the injector’s suction capacity is too low, the switch body that has

been pushed upwards by the upward flow in the suction pipe, drops and the chemical dosing is turned

off. This ensures that dosing only occurs in vigorously flowing water and the two chemicals cannot

meet in the open area.

In the same way, the floating valve (47) blocks this inlet into the flushing tub in the event of a downtime

or malfunction of the device. However, these actions cannot guarantee an absolute separation from

the circulation circuit. If this is required, securely sealing shut-off valves must be installed in the inlet

and dosing lines; either non-return valves or self-closing pneumatic valves, depending on the pressure

situation. Pay attention to the pressure loss caused by the valves during operation.

The

(46) conducts the – nearly chlorine-free – excess water that occurs in case of

the “water-max” fault to the drain.

The pressure retention valve (32) (only for CPR Touch XL) is used to supply the measuring cell block

with a constant pressure and prevents the overflow of the flushing tub when no water is suctioned off.

The pressure retention valve is preset ex works; however, it may have to be adapted to the local con-

ditions during commissioning, if necessary.

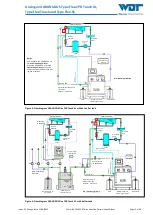

To prevent the chlorine granulate and the acid from meeting and reacting with each other in the open

part of the dissolving unit, the following safety package has been installed:

The dosing of the two chemicals occurs in set cycles with pauses between the dosing processes.

The power supply of the two dosing motors is locked via a relay system in such a way that both

motors can never be running at the same time!

The water supply and water flow are monitored by the pressure switch (31), level switch (48) and

flow switch (42).

Dosing only takes place when the water flow is ensured.

In the event of deviation from the set target values (e.g., water-min/max, pressure flow, etc.) the

dosing system is turned off and a corresponding fault indication is displayed.

ATTENTION!

The use of sulphuric acid is generally possible up to a concentration of 50%. With higher

concentrations or when using other acids (e.g., hydrochloric acid, dissolved sodium hydro-

gen sulphate, etc.), pay attention to a change in dosing performance and/or increased cor-

rosiveness! We recommend consultation with the manufacturer!

Summary of Contents for GRANUDOS Flex-CPR Touch XL

Page 74: ......