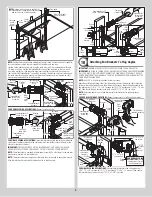

ratchet wheel or the mark on the winding shaft. After 2 to 3 turns, remove the ratchet wrench

and adjust the counterbalance lift cable on the left side. Ensure counterbalance lift cables are

in the first groove of the cable drums, as shown in Step Adjusting Counterbalance Lift Cable.

NOTE:

Single spring applications require no spring winding on the left hand side, but lift

cable tension needs to be adjusted.

FOR SINGLE SPRING APPLICATIONS:

Return to the right hand end bracket and continue

winding the spring to the required number of turns for your door following the double spring

instructions below. Place pawl knob in lower position.

FOR DOUBLE SPRING APPLICATIONS:

Either use the black tooth on the ratchet wheel for

winding reference or place a mark on the winding shaft and end bracket. Place the ratchet

wrench with 5/8” socket and a 3” ratchet extension onto the left hand winding shaft end.

To wind the spring, rotate the winding shaft clockwise, while watching the black tooth on

the ratchet wheel or the mark on the winding shaft. Rotate the winding shaft to the required

number of winding turns for your door. Then return to the right hand side and wind the right

hand spring to the required number of turns. Place pawl knob in lower position on both sides.

IMPORTANT:

MARK THE NUMBER OF SPRING TURNS ONTO THE END BRACKET WARNING

TAG.

WINDING SPRING TURN CHART

DOOR HEIGHT

SPRING TURNS

6’-0”

14

6’-3”

14-1/2

6’-5” - 6’-6”

15

6’-8” - 6’-9”

15-1/2

7’-0”

16

7’-3”

16-1/2

7’-6”

17

7’-9”

17-1/2

8’-0”

18

NOTE:

Since total turns to balance door can deviate from winding spring turn chart values by

± 1 turn, adjustments to the recommended number of turns may be required after rear back

hangs are installed.

Counterbalance

lift cable

Right hand

end bracket

Pawl knob

in upper

position

5/8”

Socket

Ratchet

wrench

Winding

shaft

3” Ratchet

extension

Marks

Counterbalance

lift cable

Left hand

end bracket

Pawl knob

in upper

position

5/8”

Socket

Ratchet

wrench

3”

Extension

Marks

Winding

shaft

Securing Drum Wraps (Optional)

23

NOTE:

If you don’t have drum wraps, then skip this step. Refer to Package Contents / Parts

Breakdown, to determine if you have drum wraps.

Starting on the left hand side, position the left hand drum wrap, as shown. Slide the left hand

drum wrap over the cable drum assembly.

IMPORTANT:

PULL THE COUNTERBALANCE LIFT CABLE AWAY FROM THE HEADER TO

CLEAR THE LATCH, WHILE SIMULTANEOUSLY SLIDING THE DRUM WRAP AGAINST THE LAST

RIB UNTIL THE THREE CATCHES ENGAGE THE 3

RD

RIB.

Secure the hinge latch by rotating upward until a distinct snap is felt. Confirm the catch is

fully engaged by lightly tugging on it. Repeat the same process for right hand side.

Left hand

drum wrap

Cable

drum

Re-engage

hinged latch

3

rd

rib

Counterbalance lift

cable. Pull to clear latch

Left hand

drum wrap

3

Catches

Left hand

drum wrap

Last

rib

NOTE:

Repeat the same process for right

hand side.

Attaching Rear Back Hangs

24

IMPORTANT:

HOLD THE DOOR DOWN TO PREVENT IT FROM RISING UNEXPECTEDLY IN THE

EVENT THE SPRING(S) WERE OVER-WOUND AND CAUTIOUSLY REMOVE LOCKING PLIERS

FROM VERTICAL TRACKS.

Raise the door until the top section and half of the next section are in the horizontal track

radius. Do not raise door any further since rear of horizontal tracks are not yet supported.

WARNING

RAISING DOOR INTO THE LOOSE HORIZONTAL TRACKS CAN RESULT IN

DOOR FALLING AND CAUSE SEVERE OR FATAL INJURY.

Clamp a pair of locking pliers onto the vertical tracks just above the second track roller on

one side, and just below the second track roller on the other side. This will prevent the door

from raising or lowering while installing the rear back hangs.

Using the chart below, select the appropriate perforated angle (may not be supplied). Fabri-

cate and install rear back hangs, as shown.

Perforated Angle Gauge Weight Limitations:

Perforated Angle Gauge

Door Balance Weight

2” x 2” x 12 Gauge

Less Than 800 lbs.

1-1/4” x 1-1/4” x 13 Gauge

Less Than 305 lbs.

1-1/4” x 1-1/4” x 15 Gauge

Less Than 220 lbs.

1-1/4” x 1-1/4” x 16 Gauge

Less Than 175 lbs.

NOTE:

If an opener is installed, position horizontal tracks one hole above level when securing

them to the rear back hangs.

WARNING

KEEP HORIZONTAL TRACKS PARALLEL AND WITHIN 3/4” TO 7/8”

MAXIMUM OF DOOR EDGE, OTHERWISE DOOR COULD FALL, RESULTING

IN SEVERE OR FATAL INJURY.

WARNING

MAKE SURE BACK HANGS ARE BRACED SUFFICIENTLY TO RESIST ANY

MOTION DURING SPRING APPLICATION AND DOOR TRAVEL. IF BACK

HANGS PIVOT OR DEFLECT, ADD REINFORCEMENT UNTIL THEY REMAIN

FIRM AND STATIONARY. ANY BACK HANG THAT HAS BENT MUST BE

REPLACED.

IMPORTANT:

DO NOT SUPPORT THE WEIGHT OF THE DOOR ON ANY PART OF THE REAR

BACK HANGS THAT CANTILEVERS 4” OR MORE BEYOND A SOUND FRAMING MEMBER.

NOTE:

If rear back hangs are to be installed over drywall, use (2) 5/16” x 2” hex head lag

screws and make sure lag screws engage into solid structural lumber.

WARNING

FAILURE TO ASSEMBLE AND ATTACH REAR BACK HANGS PROPERLY

ACCORDING TO THE ABOVE INSTRUCTIONS MAY RESULT IN DOOR

FALLING WHEN RAISED, CAUSING SEVERE OR FATAL INJURY.

NOTE:

Perforated angle must be attached to sound framing members and

nails should not

be used

.

10