3

Test No. 1 - Differential Test

Make sure that the test kit is at the same elevation as the device

being tested.

1. Remove the two screws from hood and remove hood so that

vent is visible.

2. Turn test kit on, wait until self check is complete.

3. Connect hose from test cock to VA HIGH.

4. Open test cock, then VA, (VB LOW should be opened and

remain open through the test). Bleed hose and test kit of air,

when bleeding hose fi ll vent with water, shut off VA.

5. Close #2 shutoff, then close #1 shutoff.

6. Press

PRINT HEADER

button. Wait until header stops print-

ing. Press

START TEST RESUME

button.

7. Slowly unscrew bleed screw on SVB (about three turns).

8. When dripping from bleed screw stops, and gauge reading

settles, this is the check differential. This must be 1 PSI or

greater.

9. Press

PAUSE STOP

button.

Test No. 2 - Air Inlet (Vent Opening)

10. Press

START TEST RESUME.

11. Slowly open VA and watch vent, with fi nger over

DISPLAY

HOLD

button. When the water level above the vent starts to

drop this is the vent opening press

DISPLAY HOLD

button.

This will record the vent opening point. This value must be 1

PSI or greater.

12. Visually inspect vent to ensure that vent goes to full open

position when the pressure is at zero.

13. Press

PAUSE STOP TEST

button twice.

14. Tighten bleed screw, close test cock and reinstall hood, open

shutoff #1, open shutoff #2, remove hose. Testing is com-

plete.

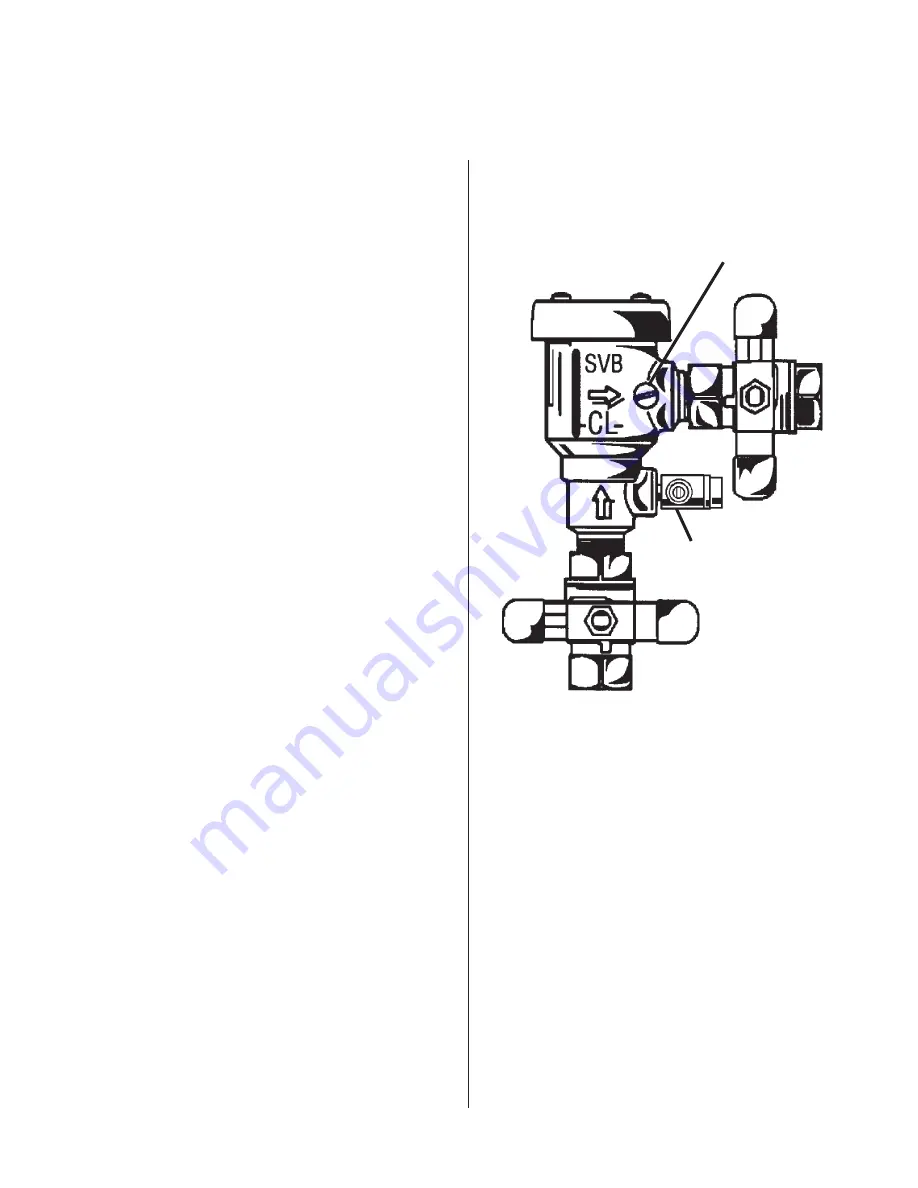

008QT

Bleed Screw

Test Cock

Test Procedure for Anti-spill, Anti-siphon Vacuum Breaker (SVB)

IS-TK-DL.indd 3

9/5/08 2:18:58 PM