13 of 16

© 2005 D 704 - 04/05

As in any troubleshooting procedure, it is important to isolate the problem as much as possible. By using the Error Messages located on

page 14, the troubleshooting process can be greatly simplifi ed. When an error message is displayed on the RMC, refer to the error mes-

sages on page 14 to identify the cause of the error and use standard testing procedures to confi rm the fault. If you suspect an external

wiring fault, return to step three and carefully check all external wiring connections.

Once the fault has been corrected, press any button on the face of the control to clear the error message.

TEST ROUTINE

The main control functions of the RMC can be tested by pressing and holding the UP button for more than three (3) second. After the

UP button has been pressed for more than three (3) second, the RMC enters the following sequence.

Step One

The variable speed output is increased from 0% to 100% over 10 seconds.

Step Two

The variable speed output is decreased from 100% to 0% over 10 seconds.

Step Three

The System Pump is turned on for 10 seconds.

Step Four

The Boiler Contact is turned on. After 10 seconds, the Boiler Contact and the

System Pump contact are turned off. The RMC continues normal operation.

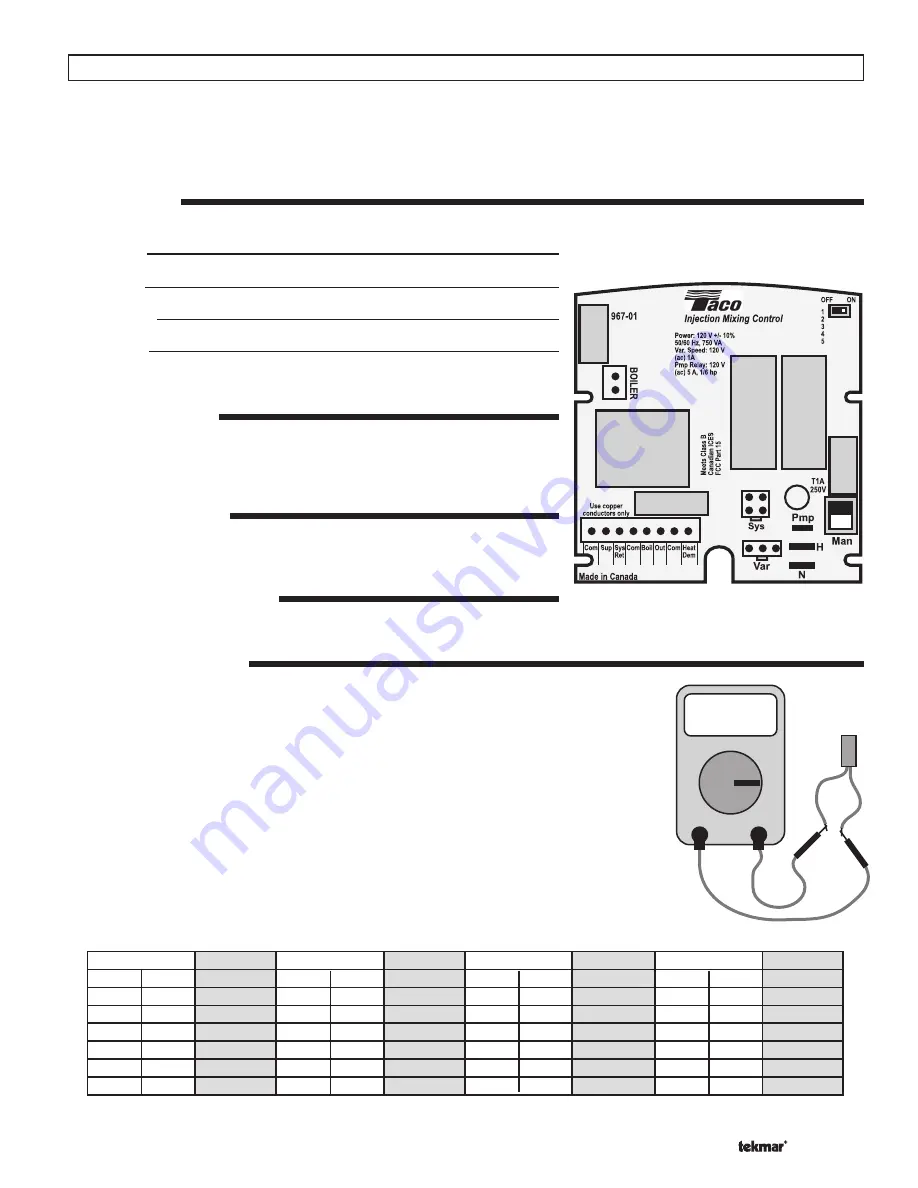

MANUAL OVERRIDE

In the event that the RMC fails to operate, a manual operation switch is located

on the RMC’s circuit board. When the manual operation switch is set to Man, the

variable speed injection pump and the system pump outputs are turned on. This

operation continues until the manual switch is returned to its original position.

FUSE REPLACEMENT

The Variable Speed output of the RMC is fused protected. This fuse is located on

the circuit board on the back of the RMC. This is a fi eld replaceable item.

Fuse rating: 1 A 1/12 hp, fuse T1 A 250 V

ADJUSTMENT OF SETTINGS

If the outdoor temperature is cold and the rooms are cold, increase the MIX DSGN

setting by 5°F (3°C) per day.

TESTING THE SENSORS

Do not apply voltage to the sensor or to the sensor input of the control as this will result in damage

to either the sensor, the control, or both the sensor and the control.

A quality testing meter capable of measuring up to 2,000,000 ohms and a good quality digital ther-

mometer are required to test the sensors. If a digital thermometer is not available, place a second

sensor next to the original sensor and compare the readings.

Begin by measuring the temperature at the sensor location using the digital thermometer. Next,

measure the resistance of the sensor using the testing meter. Ensure that the sensor is disconnect

from the control at the time of testing. Using the reference chart below, determine the sensor’s

temperature. Compare the sensor’s temperature to that measured by the digital thermometer. The

two temperature readings should be close.

If the sensors temperature is too high, this can indicate that there is a partial short in the sensor

wiring. If the sensor’s temperature is too low, this can indicate that there is a loose connection or

break in the sensor wiring. Isolate and repair the problem. If the problem is isolated to the sensor,

replace the sensor.

Troubleshooting

OHM

-30

-20

-10

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

-34

-29

-23

-18

-12

-7

-1

4

10

16

21

27

32

38

43

49

54

60

66

71

77

82

88

93

234,000

165,000

118,000

85,500

62,500

46,000

34,500

26,000

20,000

15,500

12,000

9,300

7,300

5,800

4,700

3,800

3,100

2,500

2,000

1,700

1,400

1,200

1,000

800

Temperature

Resistance

F

C

Ohms

Temperature

Resistance

F

C

Ohms

Temperature

Resistance

F

C

Ohms

Temperature

Resistance

F

C

Ohms