CHIMNEY TYPES: USA ONLY

The stove must be connected to a UL listed residen-

tial type HT and Building Heating Appliance chimney

installed in accordance with the manufacturers

instructions or a masonry chimney constructed in

accordance with NFPA211 Chimney Vents and Solid

Fuel Burning Appliances.

CHIMNEY TYPES: CANADA ONLY

The stove must be connected to an Underwriters

Laboratories of Canada labelled factory built 650

o

C

chimney, installed in accordance with the manufac-

turers instructions or in a lined masonry chimney

acceptable to the Authority having jurisdiction.

CHIMNEY CONNECTOR

The chimney connector is a smoke pipe used to

connect the Waterford Erin 90 T/V & R/V Stove to

the chimney described above. The chimney con-

nector must be made of Corrosion Resistant Steel,

24 gauge or heavier (Black or Blued or equivalently

treated steel). Be sure to fasten the chimney con-

nectors together and also to the flue outlet of the

stove through the two holes provided, use at least

two screws for each joint. Be sure that the joints are

tight and fully secured.

CHIMNEY CONNECTOR USA ONLY

Connectors should maintain a pitch or rise of at least

1/4” to the foot from the stove to the chimney. It

should be installed so as to avoid sharp turns or

other construction features that would create exces-

sive resistance to the flow of flue gases. It should be

securely supported with joints fastened with sheet-

metal screws, rivets, or other approved means. The

entire length of a connector should be readily acces-

sible for inspection, cleaning, and replacement.

The connector may pass through walls or partitions

constructed of combustible materials provided the

connector is either listed for wall pass-through or is

routed through a device listed for wall pass-through

and is installed in accordance with the conditions of

the listing. Any unexposed metal that is used as part

of a wall pass-through system and is exposed to flue

gases shall be constructed of stainless steel or other

equivalent material that will resist corrosion, soften-

ing, or cracking from flue gas at temperatures up to

982

o

C.

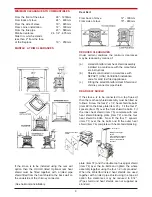

CONNECTING TO MASONRY CHIMNEY

The connector to a masonry chimney must extend

through the wall to the inner face or liner but not

beyond, and must be firmly cemented to masonry.

The connector may pass through walls or partitions

construction of combustible material to a masonry

chimney provided the connector system selected is

installed in accordance with the proper clearances

and conditions. (See figs. A,B,C,D page 8)

THIMBLES

Thimbles for chimneys or vent connector should be

of fire clay (ASTM c 315, Specifications for Clay Flue

Linings) galvanised steel of minimum thickness of

24 gauge, or material of equivalent durability.

Thimbles should be installed without damage to the

liner. The thimble should extend through the wall to,

but not beyond, the inner face of the liner and should

be firmly cemented to masonry.

Thimbles should be located to provide adequate

pitch or rise of chimney or vent connectors and,

where the ceiling above the appliance is constructed

of combustible material, the location of the thimble

should provide minimum clearance required for the

connector as specified in Section under minimum

clearances to combustibles.

Insulation material used as part of wall pass-through

system should be of non-combustible material and

should have a thermal conductivity of 1.0 Btu.in./ft.F

(4.88kg.cal/hr.m.C) or less. All clearances and thick-

nesses are minimums; larger clearances and thick-

nesses are acceptable. Any material used to close

up an opening for the connector should be of non-

combustible material. A connector to a masonry

chimney, except for system 2 (Under heading

Chimney Connector Systems, Thimbles and

Clearances), shall extend to piece through the wall

pass-through system and the chimney wall to the

inner face of the flue liner, but not beyond.

CHIMNEY CONNECTOR SYSTEMS, THIMBLES,

AND CLEARANCES FROM COMBUSTIBLE

WALLS

1.

Minimum 31/2” thick brick masonry wall

framed into combustible wall with a min. of

12” brick separation from clay liner to com

bustibles. Fire clay liner (ASTM C315 or

equivalent) min. 5/8” wall thickness, should

run from outer surface of brick wall to, but not

beyond, the inner surface of chimney flue

liner and should be firmly cemented in place.

2.

Solid insulated listed factory-built chimney

length of the same inside diameter as the

chimney connector and having 1” or more of

insulation with a min. 9” air space between

the outer wall of the chimney length and

combustibles. The inner and end of the

chimney length shall be flush with the inside

of the masonry chimney flue and shall be

sealed to the flue and to the brick masonry

7