PREINSTALLATION INSTRUCTIONS FOR DEALERS:

BYPASS VALVE:

3

The manufacturer has preset the water treatment unit’s sequence of cycles, cycle times, salt dose,

exchange capacity and salt dose refill time.

The dealer

should read this page and guide the installer regarding hardness, day override,

and time of regeneration, before installation.

For the installer

, the following must be used:

• Program Installer Settings: Hardness, Day Override (preset to 12 days), and Time of

Regeneration (preset to 2 a.m., with brine tank refill to occur four hours prior; see

Operating Displays and Instructions for more details)

• Read Normal Operating Displays

• Set Time of Day

• Read Power Loss & Error Display

• Be sure system and installation are in compliance with all state and local laws and regulations.

For the homeowner

, please read operating displays and instructions.

WATER SOFTENERS:

During operation, the normal user displays are

time of day

or

gallons remaining before regeneration

will occur.

Days remaining

is an optional display but is not normally used. Each of these can be viewed by pressing

NEXT

to scroll through them. When stepping through any displays or programming, if no buttons are

pressed within 5 minutes, the display returns to a normal user display. Any changes made prior to the

5 minute time out are incorporated.

To quickly exit any Programming, Installer Settings, etc., press

CLOCK

. Any changes made prior to

the exit are incorporated. If desired, two regenerations within 24 hours are possible with a return to

the preset program. To do a

double regeneration

:

1. Press the

REGEN

button once. “REGEN TODAY” will flash on the display.

2. Press and hold the

REGEN

button for five seconds until a regeneration begins.

Once the valve has completed the immediate regeneration, the valve will regenerate one more time

at the preset.

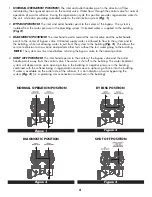

The bypass valve is typically used to isolate the control valve from the plumbing system’s water pressure

in order to perform control valve repairs or maintenance. The 1" full flow bypass valve incorporates four

positions, including a diagnostic position that allows a service technician to have pressure to test a system

while providing untreated bypass water to the building. Be sure to install bypass valve onto main control

valve, before beginning plumbing. Or, make provisions in the plumbing system for a bypass. The bypass

body and rotors are glass-filled Noryl

®

and the nuts and caps are glass-filled polypropylene. All seals are

self-lubricating EPDM to help prevent valve seizing after long periods of non-use. Internal “O” Rings can

easily be replaced if service is required.

The bypass consists of two interchangeable plug valves that are operated independently by red arrow

shaped handles. The handles identify the direction of flow. The plug valves enable the bypass valve to

operate in four positions.