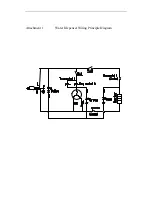

I. Working principle

The water dispenser is a kind of device, which provides bottled drinking water (distilled water,

pure water, mineral water, etc.) or daily life water treated through purification equipment to people for

drinking, after being heated, cooled or at its original water temperature.

Diversion and shunt functions: through the effect of atmospheric pressure, guide 3 gallons or 5

gallons of commercial water contained in a large bottle, through the bottle supporter, into their tanks

respectively, to realize the purpose of auto provision and supplementation of water.

Heating function: guide the water into a stainless tank of about 1.5L, heat the water and

automatically maintain it at above 90

•

, by means of a built-in 420W heating tube automatically

controlled by a 92

•

temperature controller, for instant use.

Cooling function: through a complete set of “compressor – condenser – evaporator” system, the

compressor cool the pure water inside the cool tank by using R134a as the cooling medium. Under the

auto control of the temperature controller, keep the temperature of water and refrigerator below 10

•

for instant use.

II. Main Technical Parameters

Power Supply

115V~/60Hz

Surrounding

Temperature

10

•

-38

•

Relative humidity

•

45

•

-75

•

Height above sea level

Less than 1000m

Heating power

420W

Ability to prepare hot

water

5L/h

Cooling power

100W

Ability to prepare cold

water

1L/h

Service conditions

In the ambient air, there is no flammable, explosive and corrosive gas and

conducting dust, and no strenuous shock.

III. Main Components and Their Functions

Here we introduce the water dispenser’s major components and their functions. for the drawings, see

Attachment 2.

Bottle supporter(2): a bottle head is connected to support the drinking water bottle.

Cold tank assembly(6): the cold tank is used for preparing and storing cold water and also for shunt; a

temperature sensor is fixed in the cold tank to determine water temperature.

Hot tank assembly(35): the hot tank contains a heating wire, one end of which connects a dry-boiling

prevention temperature controller to avoid dry boiling; a temperature sensor