7

STRAIN

RELIEF

MOUNTING

BRACKET

NUT

TIGHTEN

NUT

TO THESE

THREADS

POWER

CORD

RED

WHITE

BLACK

TERMINAL BLOCK

SILVER TERMINAL

GREEN

GROUND

SCREW

GREEN POWER CORD

GROUND WIRE

GREEN

NEUTRAL

GROUND

WIRE

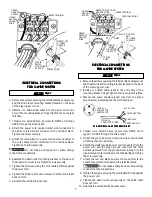

4. Thread a U.L. listed 30 amp power cord, NEMA 14-30

type ST or SRDT through the strain relief.

5. Attach the green power cord ground wire to the cabinet

with the green ground screw.

6. Attach the white (neutral) power cord conductor from the

power cord and the green ground wire from the dryer

harness (removed from the ground screw in step 3) to the

silver-colored center terminal on the terminal block. Tighten

the screw securely.

7. Attach the red and black power cord conductors to the

outer brass-colored terminals on the terminal block.

Do not make a sharp bend or crimp wiring/

conductor at the connections.

8. Tighten the screws securing the cord restraint firmly against

the power cord.

9. Tighten the strain relief nut securely so the strain relief

does not turn.

10. Reinstall the terminal block access cover.

TYPICAL 4

CONDUCTOR CORD

RED 240V

BLACK 240V

WHITE NEUTRAL

GREEN GROUND

30 AMP NEMA 14-30 TYPE SRDT OR ST

30 AMP NEMA 14-30 TYPE SRDT OR ST

30 AMP NEMA 14-30 TYPE SRDT OR ST

30 AMP NEMA 14-30 TYPE SRDT OR ST

30 AMP NEMA 14-30 TYPE SRDT OR ST

TYPICAL 4

CONDUCTOR

RECEPTACLE

POWER CORD

TIGHTEN NUT

TO THESE

THREADS

STRAIN

RELIEF

MOUNTING

BRACKET

GREEN

GROUND

SCREW

NUT

SILVER TERMINAL

GREEN

NEUTRAL

GROUND

WIRE

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

FOR 3-WIRE SYSTEM

FOR 3-WIRE SYSTEM

FOR 3-WIRE SYSTEM

FOR 3-WIRE SYSTEM

FOR 3-WIRE SYSTEM

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC Dryer

Dryer

Dryer

Dryer

Dryer

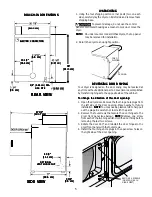

1. Remove the screws securing the terminal block access cover

and the strain relief mounting bracket located on the back

of the dryer upper corner.

2. Install a U.L. listed strain relief into the power cord entry

hole of the mounting bracket. Finger tighten the nut only at

this time.

3. Thread a U.L. listed 30 amp. power cord, NEMA 10-30 Type

SRDT, through the strain relief.

4. Attach the power cord neutral (center wire) conductor to

the silver colored center terminal on the terminal block.

Tighten the screw securely.

5. Attach the remaining two power cord outer conductors to

the outer brass colored terminals on the terminal block.

Tighten both screws securely.

Do not make a sharp bend or crimp wiring/

conductor at connections.

6. Reattach the strain relief mounting bracket to the back of

the dryer with two screws. Tighten screws securely.

7. Tighten the screws securing the cord restraint firmly against

the power cord.

8. Tighten the strain relief nut securely so that the strain relief

does not turn.

9. Reinstall the terminal block cover.

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

FOR 4-WIRE SYSTEM

FOR 4-WIRE SYSTEM

FOR 4-WIRE SYSTEM

FOR 4-WIRE SYSTEM

FOR 4-WIRE SYSTEM

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRIC Dryer

Dryer

Dryer

Dryer

Dryer

1. Remove the screws securing the terminal block access cover

and the strain relief mounting bracket located on the back

of the dryer upper corner.

2. Install a U.L. listed strain relief in the entry hole of the

mounting bracket. Finger tighten the nut only at this time.

3. Remove the green neutral ground wire from the green

ground screw located above the terminal block.