8

INST

INST

INST

INST

INSTALLA

ALLA

ALLA

ALLA

ALLATION

TION

TION

TION

TION

1. GAS CONNECTION

(Gas dryers only)

a. Remove the shipping cap from gas pipe at the rear of

the dryer.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: DO NOT

DO NOT

DO NOT

DO NOT

DO NOT connect the dryer to L.P. gas service without

converting the gas valve. An L.P. conversion kit (P/N

131776600) must be installed by a qualified gas

technician.

b. Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved

pipe from gas supply line to the 3/8 inch (0.96 cm) pipe

located on the back of the dryer. Use a 1/2 inch to 3/8

inch (1.27 cm to 0.96 cm) reducer for a connection.

Apply an approved thread sealer that is resistant to the

corrosive action of liquefied gases on all pipe connections.

c. Open the shutoff valve in the gas supply line.

d. Test all connections by brushing on a soapy water solution.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

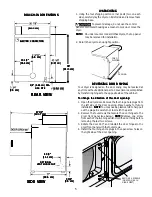

2. Connect the exhaust duct to outside exhaust system. Use

duct tape to seal all joints.

3. With the dryer in its final position, adjust one or more of the

legs until the dryer is resting solid on all four legs. Place a

level on top of the dryer. THE DR

THE DR

THE DR

THE DR

THE DRYER MUST BE LEVEL

YER MUST BE LEVEL

YER MUST BE LEVEL

YER MUST BE LEVEL

YER MUST BE LEVEL

AND RESTING SOLID ON ALL FOUR LEGS.

AND RESTING SOLID ON ALL FOUR LEGS.

AND RESTING SOLID ON ALL FOUR LEGS.

AND RESTING SOLID ON ALL FOUR LEGS.

AND RESTING SOLID ON ALL FOUR LEGS. Turn the lock

nuts on each of the four legs up toward the base of the

dryer and snug with a 1/2 inch open end wrench.

4. Plug the power cord into a grounded outlet. NOTE: Check

to ensure the power is off at circuit breaker/fuse box before

plugging the power cord into the outlet.

5. Turn on the power at the circuit breaker/fuse box.

Before operating the dryer, make sure the dryer

area is clear and free from combustible materials, gasoline,

and other flammable vapors. Also see that nothing (such as

boxes, clothing, etc.) obstructs the flow of combustion and

ventilation air.

6. Run the dryer through a cycle check for proper operation.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: On gas dryers, before the burner will light, it is

necessary for the gas line to be bled of air. If the burner

does not light within 45 seconds the first time the dryer is

turned on, the safety switch will shut the burner off. If this

happens, turn the timer to "OFF" and wait 5 minutes before

making another attempt to light.

7. Place these instructions in a location near the dryer for future

reference.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: A wiring diagram is located inside the dryer.

REPLACEMENT P

REPLACEMENT P

REPLACEMENT P

REPLACEMENT P

REPLACEMENT PAR

AR

AR

AR

ARTS

TS

TS

TS

TS

If replacement parts are needed for your dryer, contact the

source where you purchased your dryer, or call (516)371-0700

for the Wascomat Authorized Parts Distributor nearest you.

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

Destroy the carton and plastic bags after the

dryer is unpacked. Children might use them for play. Cartons

covered with rugs, bedspreads, or plastic sheets can become

airtight chambers causing suffocation. Place all materials in a

garbage container or make materials inaccessible to children.

The instructions in this manual and all other

literature included with this dryer are not meant to cover every

possible condition and situation that may occur. Good safe

practice and caution MUST

MUST

MUST

MUST

MUST be applied when installing, operating

and maintaining any appliance.

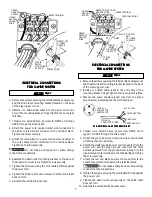

Lint Blade Retaining Pin Location and Orientation

Lint Blade Retaining Pin Location and Orientation

Lint Blade Retaining Pin Location and Orientation

Lint Blade Retaining Pin Location and Orientation

Lint Blade Retaining Pin Location and Orientation

Install the pins after the lint blade is installed.