WINCH MANUAL

TROUBLESHOOTING

10

Problem

Cause

Solution

Winch does not does not turn

Insufficiently hydraulic system pressure.

Check relief valve regulate pressure.

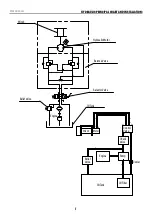

Improper connections of hydraulic system, no

oil into motor.

Check all the plumbing fixtures according to the

working principle chart.

Defective directional control valve.

Motor runs but drum does not turn

Clutch not engaged

Turn clutch to the High or Low speed position. If

problem persists, ask a technician to check and

repair.

Motor runs slowly or without normal power

Insufficient pressure or oil flow

Bump is not suitable or defective. Change a new one

or a suitable one

Insufficient fluid in the system

Check fluid level. Add fluid until full.

Wrong winch working direction.

Change the connection of balance valve and motor.

Winch cannot spool off wire rope with load

smoothly.

Wrong winch working direction.

Change the connection of balance valve and motor.

Winch brake not working normally.

Hydraulic pressure remnants in brake while

winch stop.

Use bigger back oil pipe.

Wrong winch working direction

Change the connection of balance valve and motor.

TROUBLESHOOTING

WARRANTY*

BPE Solutions North America are the sole distributors of these

WARRIOR WINCHES and associated brands/equipment.

BPE Solutions North America (“seller” or BPE) warrants to the original

retail buyer only (“Buyer”) that any mechanical component of this genuine

winch (“product(s)”) are free of defects in material and workmanship for

the lifetime of the winch.

The electrical components (including the motor, contactor, and switches)

will be free of defects in material and workmanship for a period of (3) three

years (36 Months) from the original purchase provable date of purchase

Any product BPE Solutions North America determines to be defective

will be repaired or replaced at our (BPE Solutions North America) sole

discretion without charge to the Buyer upon Buyer’s compliance with

this procedure. Seller or its Authorized Agent may make reasonable

charges for parts and(or) labour for repairs not covered by this Lifetime

Limited Warranty. None warrantable returns will be charged at BPE

Solutions North America standard rates. The warranties set forth herein

are exclusive and in lieu of all other warranties, whether oral or written,

express or implied.

If in the event your product becomes faulty

within your warranty period

To obtain service or repair under this warranty, the Buyer shall mail, ship

or otherwise deliver to the manufacturers address, at the Buyers expense;

(1) the Product, (2) a written description of the problem, (3) Buyers name,

address and contact number, (4) copy of the original purchase receipt or

BPE Solutions North America can arrange a suitable collection method

(Charges apply).

Warranty Exclusions

The Warranty does not cover the cost of labour or transportation/shipping

charges for the replacement or installation of defective part(s).

This warranty does not apply to defects of the Product caused by;

(1) normal wear and tear, (2) failure to comply with any installation,

maintenance or subjecting the product to loads in excess of the loads

written/listed in the owners manual or as detailed upon the Sellers

website, (3) alteration or modification by any parties other than the

manufacturer, (4) misuse, abuse, neglect, accidents, Acts of God,

terrorism or (5) failure to correctly use the item according to the owners

manual (7) other causes beyond the control of the Seller after delivery of

the Product to the Sellers Authorized Agent.

Other Exclusions

This Warranty does not cover steel cables, synthetic ropes, fairleads,

wireless remotes or any exterior finishes outside thirty (30) Days from

purchase.

BPE Solutions North America shall not be responsible or liable for any

indirect or consequential damages. These consequential damages may

include, but are not limited to, lost profits or loss of use, down time or

damage to other person(s) equipment.

BPE Solutions North America reserves the right to change the Product

design without notice. BPE Solutions North America reserves the right to

replace any part or whole unit with a newer design of the same function.

Summary of Contents for 13JR02H-CAD

Page 12: ...Winch Manual SPECIFICATIONS 12 WINCH ASSEMBLY DRAWING 13JR02H CAD...

Page 15: ...Winch Manual SPECIFICATIONS 15 WINCH ASSEMBLY DRAWING 15JR02H CAD...

Page 18: ...Winch Manual SPECIFICATIONS 18 WINCH ASSEMBLY DRAWING 20JR02H CAD...

Page 21: ...Winch Manual SPECIFICATIONS 21 WINCH ASSEMBLY DRAWING 25JR02H CAD...

Page 24: ...Winch Manual SPECIFICATIONS 24 WINCH ASSEMBLY DRAWING 30JR02H CAD...