5

Subfloor Preparation

1

2

3

4

5

Wooden Subfloors

• Ensure adequate underfloor ventilation

• Existing floorboards need to be securely fixed and if necessary

pre-levelled with a latex/cement self-levelling compound to give a

flush fit for the subsequently applied WBP plywood (18mm) or an

Insulated tile backer board (Warmup® Insulation Boards).

• A rigid base is essential - Fixing WBP plywood or Warmup®

Insulation Board to joists will not provide a suitable floor finish for

accepting tiles.

• Refer to BS5385: Part 3: 1999, clause 14.4 for more information

on sealing the backs and edges of the WBP plywood before fixing.

• The above recommendations apply to floors of small areas as

advised in clause14.4 of BS 5385: Part 3: 1999.

Concrete Subfloors

• Ensure you use an extruded polystyrene building or tile backer

board (Warmup® Insulation Board) if installing your mat onto a

cement-based floor.

• Fixing the board should be as per the manufacturer’s

instructions.

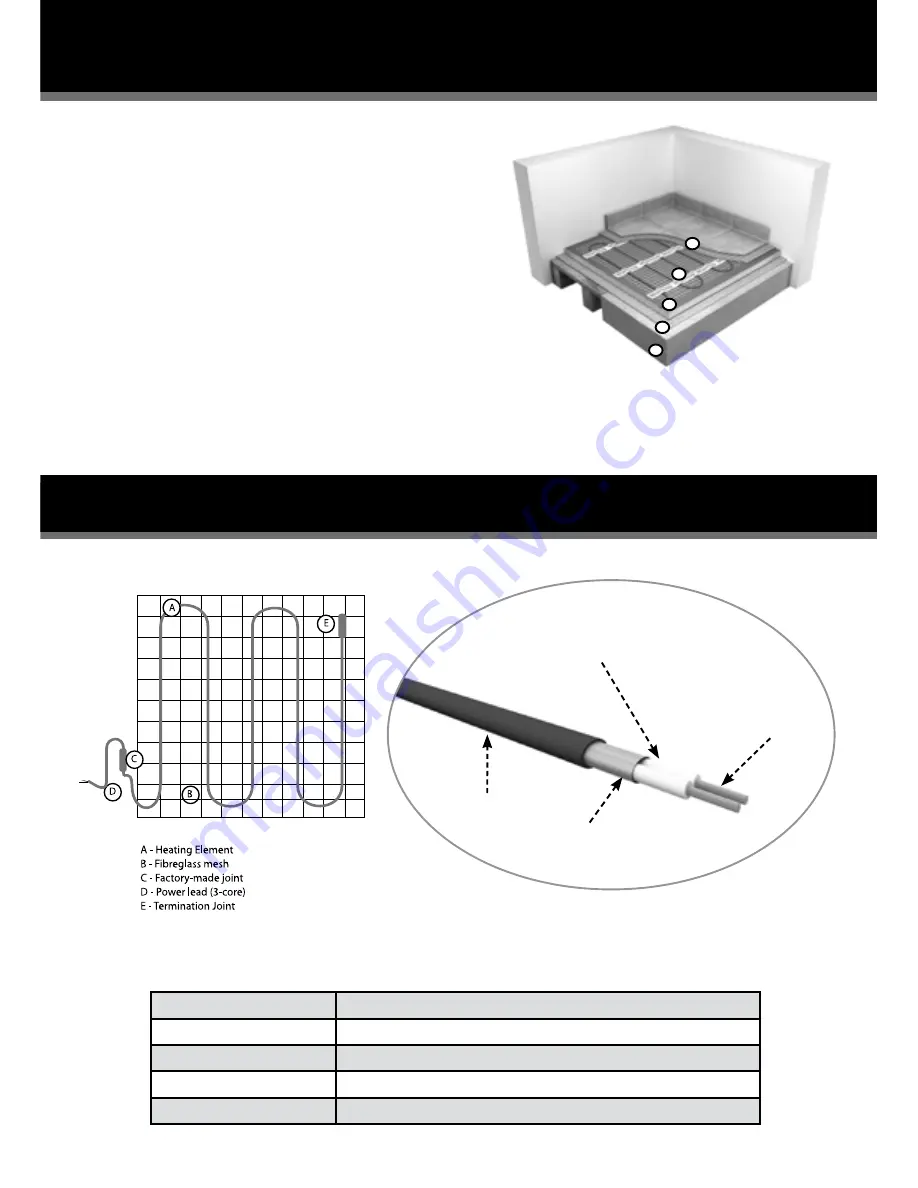

About the mat

1. Concrete/ Timber Subfloor

2. Flexible Adhesive

3. Wamup® Insulation Board

4. Warmup® Underfloor Heating Mat

5. Flexible Adhesive & Tile

NOTE:

Warmup thermostats can switch up to 16 amps. If

you are installing more than two heaters you may

require a junction box.

The mat is made up of

The mat is available in 2 different wattages 150W/m2 and 200W/m2. Each mat

is designed to produce a specific amount of heat based on its length. For this

reason you must never shorten the mat.

Advanced Fluoropolymer

Insulation

Earth Braid

Multistrand Twin

Conductors

Polyolefin

Voltage

230VAC ~ 50Hz

Min bending radius

25mm

Ip rating

IPX7

Min Spacing

50mm

Min installation temp

5°C