Rev. 1.5

Operating Manual Table-top Greasing Device TBV-H-0x-xx

Page 16 of 35

Walther Systemtechnik GmbH

–

D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de

–

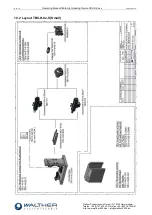

9 Troubleshooting

9.1 General Information

IMPORTANT

First check all supply lines for proper connection and serviceability

.

In case of serious problems which cannot be resolved, please contact the Walther Systemtechnik GmbH

customer service.

Fault

Possible cause

Action

Valve is actuated, but

no lubricant is ejected.

Does the feed pump

transport lubricant?

Check feed pump.

See operating manual of feed pump.

Check venting screw of feed pump.

See operating manual of feed pump.

Leakage

Check dosing valve.

Permanent signal from

sensor

Sensor defective

Exchange sensor

Dosing piston not in end

position

Check dosing valve; check settings of dosing

volume

No signal from sensor

Broken cable

Exchange cable

Sensor defective

Exchange sensor

Loose cable

Check cable connections

Retainer loose

Tighten retainer

Sensor loose in retainer Tighten sensor to retainer

Permanent signal from

proximity switch

Air piston permanently

in starting position

Check dosing valve

Proximity switch

defective

Exchange proximity switch

No signal from proximity

switch

Air piston not in starting

position or defective

Check dosing valve

LED defective

LED or sensor defective Exchange cables, exchange sensor

Air pockets in grease

system.

Air pockets in grease

Container.

Air pockets in tubing.

Disconnect tubing to dosing valve. Drain a

quantum of grease. Restart with dosage

adjustment screw set to maximum.