26

27

Clean the spray gun

•

before each change of spraying material

•

at least once a week or

•

several times a week if required by the spraying medium and depending on the

degree of fouling.

Detailed

Cleaning

1. Disassemble the spray gun

2. Clean the air cap (Pos. 1) and the material nozzle (Pos. 3) with a soft brush and

cleaning fluid.

3. Clean all other components and the gun body with a soft cloth and cleaning fluid.

4. Coat the following parts with a thin layer of grease:

•

Molla dell'ago (Pos. 16)

•

all sliding parts and bearing points.

The moving internal parts must be greased at least once a week.

The springs should always be coated with a thin layer of grease. For this, always use

a non-acidic, non-resinogenic grease and a soft brush. Assemble the gun again in

reverse order.

8

Trouble shooting

Warning

Prior to any retooling the spray gun should be depressurized state, i. e. atomising air

as well as the material pressure - risk of injury.

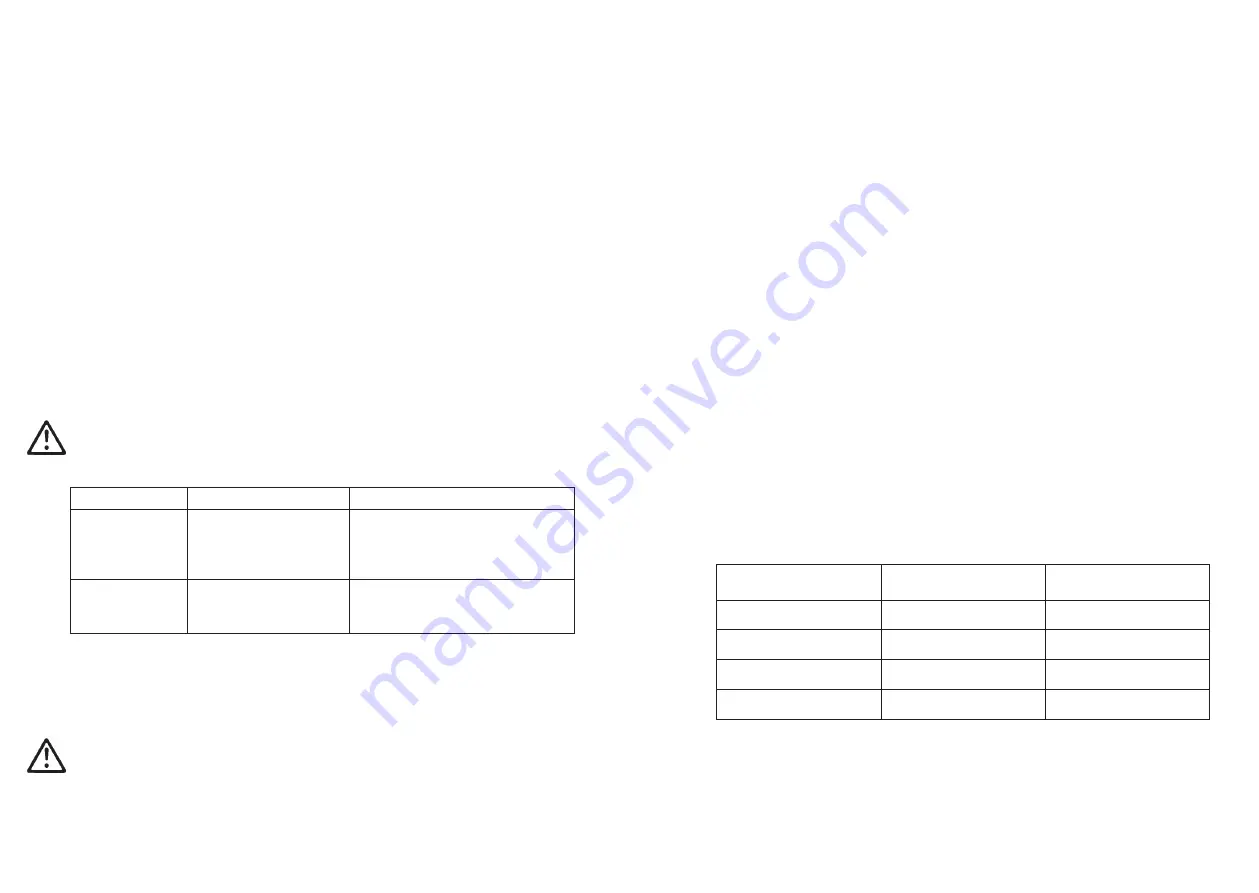

Error

Cause

Troubleshooting

Gun drips /

sprays when not

in use

Air pressure too low

Material hose too hard

Increase air pressure to at least

2 bar

use softer hose

Pulsating or

shimming

spray jet

Material volume too low

Wrong air cap position

Fill in material

Adjust air cap position

9

Disposal of cleaning and servicing substances

Waste spraying media and waste material from cleaning and servicing must be dis-

posed of in accordance with all applicable local and national regulations.

Warning

Observe the instructions issued by the manufacturers of the spraying and cleaning

material at all times.The improper disposal of waste material endangers the health of

human beings and animals!

10

Technical data

Net weight:

780 g

Material nozzles available:

0,5 • 0,8 • 1,0 • 1,2 • 1,5 • 2,0 mm ø

Aircaps:

Round-jet aircap V 10 109 01 053

(for material-nozzle sizes 0,5-1,5 mm)

Round-jet aircap V 10 109 01 203

(for material-nozzle sizes 2,0 mm)

Connection:

Air connection:

G 1/4"

Material Inlet:

Silicon hose 4 x 8 mm

ø transparent

or PVC hose 5 x 1,5 mm

ø

Pressure ranges:

Min. input air pressure

2 bar

Max. input air pressure

8 bar

Max. material pressure

1,5 bar

Max. operating temperature

of the Spray gun:

43°C

Noise level

(measured at approx.

1 m from the spray gun)

:

83 dB(A)

Air consumption:

Atomising air pressure

SIL 42

SIL 43

1 bar

56 l/min

71 l/min

2 bar

98 l/min

130 l/min

3 bar

140 l/min

180 l/min

4 bar

179 l/min

222 l/min

Right to effect technical changes reserved.