Service and Maintenance

BXTR5224

Wood Chipper

54

6.14 Upper Feed Roller Tension

Adjustment

The feed rollers pull material from the hopper into the chipper.

The lower roller is fixed. The upper roller is mounted on hinged

pivot arms so it can move up and down with different sizes of

material. Spring tension on the upper pivot arms hold the roller

down on the material as it is fed into the chipper.

Adjust spring tension tighter for smaller material, and looser for

larger material.

If spring tension needs to be adjusted, follow these steps:

Procedure

1.

On the underside of the machine, loosen the jam nuts (1)

on the spring tensioners. Hold the upper nut with a wrench

while loosening the jam nut.

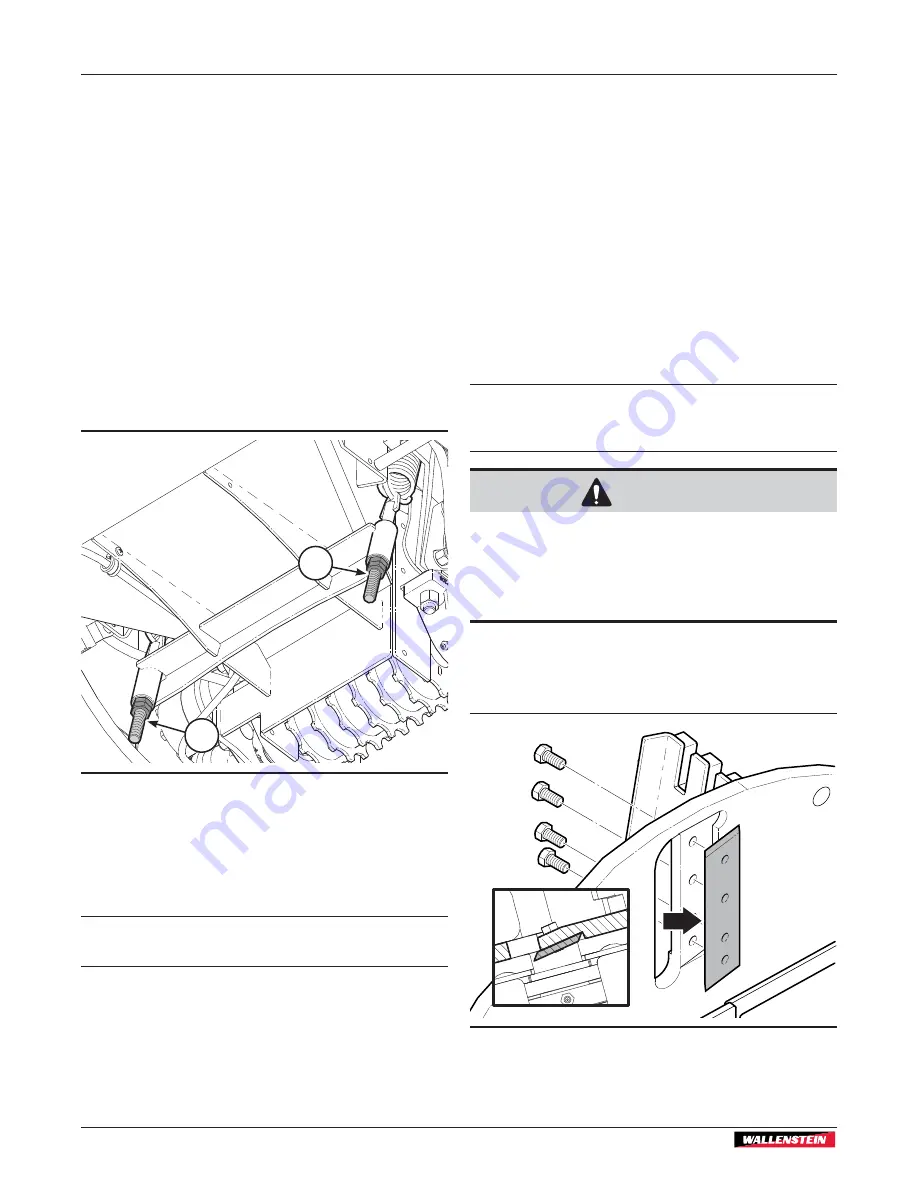

00150

Fig. 65 –

Upper feed roller tensioner (US model shown)

1

1

2.

Turn the adjuster nut to set spring tension as required. The

upper roller should grip material and move up and down

with different material sizes.

3.

Hold the adjuster nut with a wrench and tighten the jam nut.

IMPORTANT! Set tension on both sides equally. Measure

the length of adjustment threads as a check.

6.15 Rotor Blades – Changing

Check rotor blade sharpness daily.

Check blade sharpness more often if processing material with

a lot of sand, soil or dirt in it. If the chipper is not pulling the

material or material has to pushed into the chipper, the rotor

blades are probably dull.

Keeping the blades sharp reduces the amount of power required

during operation. Reverse or sharpen the blades if the cutting

edge becomes dull.

Procedure

1.

Remove the blades from the rotor to sharpen. Sharpen at a

45° angle to provide the best cutting effect.

IMPORTANT! Make sure equal amount of material is

removed from each blade when sharpening to maintain

proper rotor balance.

CAUTION!

Wear heavy gloves, turn the rotor slowly, and be

aware of your hand positions. The rotor knives

are sharp and can cause cuts. Finger and hands

can become pinched or wedged between the

rotor and the rotor housing.

W032

2.

Install rotor blades with leading edge out, towards the

ledger blade. Tighten the blade mounting bolts to

45 lbf•ft

(63 N•m)

.

00152

Fig. 66 –

Rotor blade leading edge