22

VERSION 01/2018

ORDER NUMBER DOC 2385674

TOPFINISH Bell 1S

5.2

FUNCTIONAL DESCRIPTION

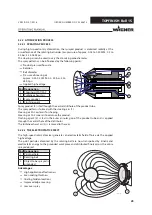

The high-speed rotary atomizer consists of a carrier ring (5), the mounted air deflecting

ring (4), the transition piece (7), the valve block (10) and the casing (11).

The casing (11) is used by the customer to mount the device.

The optical fiber (8) is used to detect signals for speed control.

Product is fed to the device via the valve block (10) and the product tube (6) located in the

axis center. This is then distributed evenly on the surface of the bell (2) via the distributor

(1).

The deposited product is atomized finely in the radial direction at the outer bell edge

through the acting centrifugal forces. The electrostatic effect supports this process.

Both the atomizing cone diameter as well as the kinetic energy of the atomized product

in the axial direction are influenced by the steering air flowing through the air deflecting

ring (4).

With the steering airs SA1 and SA2, and the electrostatic, the direction and geometry of the

spray pattern can be customized to meet the specific needs.

Specific cleaning of the bell on the inside and outside is possible by means of the bell

flushing valve (FB) without having to flush the entire product channel.

If working with water-based lacquer, the system is linked to the rest of the system via the

lacquer pillar (ion conductor) such that the paint supply has to be isolated as well.

5.2.1 FUNCTIONAL DESCRIPTION OF THE INDIVIDUAL COMPONENTS

Designation

Function

Bell plate

The bell plate atomizes the product.

The bell plate is selected depending on the product to be

processed

By selecting knurled bell plates, the drop size can be reduced

(also see Chapter

Air bearing/drive

The drive is an air motor driven by compressed air.

It is mounted using an air bearing.

The results of atomization depend on the centrifugal force,

generated by the bell plate rotating.

The size of the product droplet decreases as the speed of

rotation of the hollow shaft increases.

Air control ring

The air control ring creates the diameter of the spray pattern

and conveys the product particle to the work piece using

kinetic energy.

Product tube

The product tube centers the product nozzle in the center of

the bell plate.

The product tube transports the media (lacquer, flushing

agent) to the bell plate.

Product nozzle

The product nozzle regulates the application rate flowing into

the bell plate.

The size of the product nozzle is selected depending on the

viscosity of the coating product and the desired layer thickness.

Valve block

In its basic version, the valve block serves as an interface to the

supply pipes.