54

Super Finish 33 PRO

3

4

1

2

5

GB

REPAIRS AT THE UNIT

10.5

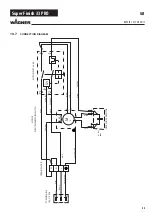

REPLACING THE POWER CABLE

This may only be carried out by a skilled elec-

trician. No liability is assumed for incorrect

installation.

Switch the unit off.

Before all repair work: Unplug the power

plug from the outlet.

Do not dismantle the sealed pressure control

valve (1) so as to ensure that the pressure set-

ting is retained.

To remove the pump, move it to an upright

position. Open the oil lock screw (5) to re-

lease any excess pressure that has built up in

the hydraulic oil housing.

1. Completely unscrew the pressure control valve (1) (span-

ner width 17 mm).

2. Remove the front cover (2) by loosening the 5 screws

using an Allen key (SW 3).

3. Loosen the cable threaded joint (3).

4. Loosen the wires in the mains terminal (4).

5. Replace the unit connecting line.

(only an approved power cable with the designation H07-

RNF with a splash-proof plug may be used).

6. Connect the green/yellow wire to the contact with the PE

sign.

7. Remount the covers carefully (do not squeeze any cables!)

8. Replace the pressure control valve in the housing and

screw into position.

10.6

TYPICAL WEAR PARTS

Despite the use of high-quality materials the highly abrasive

effect of the paints means that wear can occur at the follow-

ing parts:

Inlet valve

(spare part Order No.: 0341247)

For replacing refer to Section 10.2

(failure becomes noticeable through performance loss and/or

poor or no suction)

Outlet valve

(spare part Order No.: 0341702)

For replacing refer to Section 10.3

(failure becomes noticeable through performance loss and/

or poor suction) The outlet valve is usually considerably more

durable than the inlet valve. Thorough cleaning may already

help here.

Summary of Contents for Super Finish 33 Pro

Page 21: ...57 Super Finish 33 PRO GB ...

Page 29: ...65 Super Finish 33 PRO GB ...