49

Super Finish 33 PRO

GB

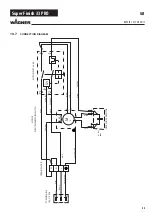

DISPLAYS AT THE UNIT / CLEANING THE UNIT

8

CLEANING THE UNIT

A clean state is the best method of ensuring operation with-

out problems. After you have finished spraying, clean the unit.

Under no circumstances may coating material rests dry and

harden in the unit. The cleaning agent used for cleaning (only

with a flash point above 21 °C) must be suitable for the coat-

ing material used.

Warm water improves the cleaning effect in

the case of water-dilutable coating materials.

•

Secure the spray gun

, refer to the operating manual of

the spray gun.

Remove and clean the tip.

•

Unit with suction system

1. Open the relief valve, valve setting

(circulation) and

switch on the device.

2. Remove the suction system from the material container,

the return tube remains over the material container.

3. Immerse the suction system into a container filled with a

suitable cleaning agent

4. Turn the pressure control valve back in order to set a mini-

mal spraying pressure.

5. Close the relief valve, valve setting

(spraying).

With coating materials containing solvents,

an earthed metal container must be used

for cleaning into which the cleaning agent is

pumped.

Caution! Do not pump or spray in container

with small opening (bunghole)!

See safety regulations.

6. Pull the trigger guard of the spray gun in order to pump

the remaining coating material from the suction hose,

high-pressure hose and the spray gun into an open con-

tainer (if appropriate, increase the pressure at the pres-

sure control valve slowly in order to obtain a higher mate-

rial flow).

7. Open the relief valve, valve setting

(circulation).

8. Pump suitable cleaning agent in the circuit for several

minutes.

The cleaning effect is increased by alterna-

tively opening and closing the spray gun.

9. Close the relief valve, valve setting

(spraying).

10. Pump the remaining cleaning agent into an open contain-

er until the pump is empty.

11. Switch off the unit

•

Unit with upper hopper

1. Open the relief valve, valve setting

(circulation).

2. Turn the pressure control valve back in order to set a mini-

mal spraying pressure.

3. Close the relief valve, valve setting

(spraying).

With coating materials containing solvents,

an earthed metal container must be used

for cleaning into which the cleaning agent is

pumped.

Caution! Do not pump or spray in container

with small opening (bunghole)!

See safety regulations.

4. Pull the trigger guard of the spray gun in order to pump

the remaining coating material from the hopper, high-

pressure hose and the spray gun into an open container (if

appropriate, increase the pressure at the pressure control

valve slowly in order to obtain a higher material flow).

5. Fill up hopper with suitable cleaning agent.

6. Open the relief valve, valve setting

(circulation).

7. Pump suitable cleaning agent in the circuit for several

minutes.

The 20 l top container can be easily removed

and emptied after cleaning.

8. Close the relief valve, valve setting

(spraying).

9. Pump the remaining cleaning agent from the hopper,

high-pressure hose and the spray gun into an open con-

tainer.

10. Open the relief valve, valve setting

(circulation) and

switch off the device.

Summary of Contents for Super Finish 33 Pro

Page 21: ...57 Super Finish 33 PRO GB ...

Page 29: ...65 Super Finish 33 PRO GB ...