41

VERSION 05/2018

ORDER NUMBER DOC 2312956

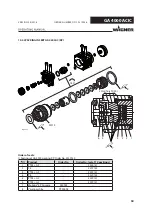

GA 4000ACIC

8

CLEANING AND MAINTENANCE

8.1

CLEANING

8.1.1 CLEANING PERSONNEL

Cleaning work should be undertaken regularly and carefully by qualified and trained

personnel. They should be informed of specific hazards during their training.

The following hazards may arise during cleaning work:

– risk to health from inhaling solvent vapors,

– use of unsuitable cleaning tools and aids.

8.1.2 FLUSHING AND CLEANING THE GUN

NOTICE

Flushing agent in the air duct!

Functional faults caused by swollen seals.

When cleaning, always operate the spray gun at at least 0.05 MPa; 0.5 bar; 7.25 psi

shaping air.

Always point the spray gun down when cleaning.

Ensure that neither paint nor flushing agent enters the air duct.

Never immerse the spray gun in cleaning agent.

The spray gun and the device must be cleaned and flushed daily. The cleaning/flushing

agents used for cleaning or flushing must correspond with the working material.

1. Relieve the pressure of gun and device.

2. Secure gun (remove the control air hose).

3. Connect the cleaning agent supply.

4. Dismount AirCoat nozzle and clean separately (see Chapter

).

5. Pressurize the cleaning agent supply to a maximum pressure of 4 MPa; 40 bar; 580 psi

and thoroughly flush the spray gun.

6. Relieve the pressure of gun and device.

7. Secure gun (remove the control air hose).

8. Clean outside of spray gun with a cleaning agent recommended by the lacquer

manufacturer and dry with a cloth or blow gun.

Summary of Contents for GA 4000ACIC-S

Page 1: ...Version 05 2018 GA 4000ACIC S GA 4000ACIC R AirCoat Automatic spray gun II 2G X B_06647...

Page 2: ......

Page 66: ......

Page 67: ......