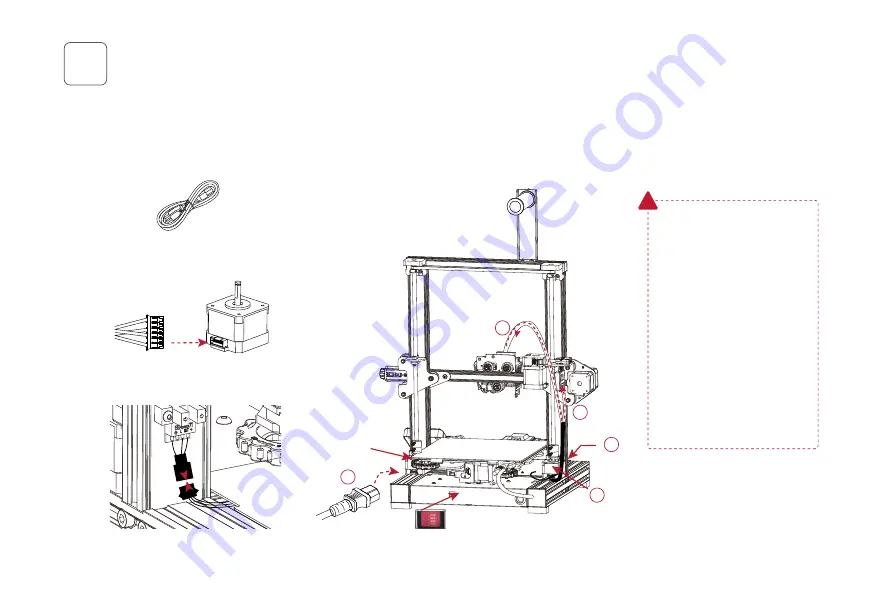

Wire connection

5

1. Connect the yellow-labeled cables with "Z1" and "Z2" on 6 pin(4 wires) ports to Z-axis motors;

将6针(4线)端口上带有黄色标签丝印“Z1”,“Z2”

的线分别与左右两个Z轴电机连接;

2. Connect the port of black cable to Z-axis limit sensor;

黑色线端口与Z轴限位传感器端口对插;

3. Insert the XE-axis assembly zcable;

插上XE轴组件转接排线;

4. Insert the extruder cable into the extruder;

插上喷头排线;

5. Plug in the power cord (as shown) and toggle the switch to turn on the power.

Z-axis motor port

Z-axis limit sensor

Power cable *1

Z-axis limit sensor

Z-axis motor

Z-axis motor

10

5

2

1

4

3

设备接线

Z轴电机接口

Z轴限位传感器接口

电源线*1

插上电源线(如示意图)拨动开关打开电源。

!

Attention

· Damage might occur if voltage is

set incorrectly. Make sure the

current input voltage matches to

your local mains

(115/230 V).

· Plug in power cord and turn

power switch to 1 to turn it on.

· Do not disconnect the cables

when the printer is powered on.

注意

· 如果电压设置不正确,可能会造成

损坏。选择正确的输入电压以匹配您

的本地电源

(115/230V)

。

· 连接电源线并将电源开关拔至I档即

可开机。

· 当机器通电时,请勿断开连接线。

Z轴限位传感器

Z轴电机

Z轴电机