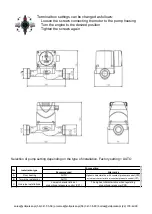

Correct installation of the pump:

NOTE:

Pumps are not suitable for pumping aggressive, flammable, explosive, high

viscosity liquids containing mineral oils, solid particles and fibrous impurities. Damage

to the pump caused by pressing the above-mentioned types of liquids is not subject to

warranty repairs.

4. PUMP INSTALLATION

Device should be used as intended. Each time before installing the pump,

check whether its condition allows operation in a way that does not endanger your

health or life. There are a few basic rules to remember when installing, operating and

operating:

ź

All installation work must be carried out only by specialized personnel

ź

All repairs and maintenance should be carried out only after disconnecting the pump

from the power supply

ź

Before dismantling, drain the system or close the shut-off valves at the pump inlet

and outlet, and wait until the temperature of the elements drops below 50 ° C.

ź

If individual components need to be replaced, please contact the manufacturer's

service.

ź

Any amendments introduced without obtaining authorization for this release the

Guarantor from any kind of liability.

ź

After completing the work, switch on all protective and safety devices again

Pump should be installed in a straight section of the installation. Shut-off valves

must be fitted on the suction pipe as well as the supply pipe. Please note that the system

pressure does not exceed the permissible operating pressure of the pump and that the

required flow direction is in line with the arrow on the pump body.

Pump should be installed in such a place that there is easy access to it (for

venting). The water in the installation must be treated and not silted under any

circumstances. The system should be filled with liquid and vented.

The pump is self-venting and does not need to

be vented before start-up. Air collected in the

pump can cause noise. This noise stops after

a few minutes of pump operation.

The pump is quickly vented by briefly starting

the pump in gear III, depending on the type

and size of the installation. The pump will be

vented when the noise level is significantly

reduced and it will be set according to the

instructions in the manual.

[email protected] (58) 341-05-06 | [email protected] (58) 341-38-80 | [email protected] (22) 100-42-99