12

A.

Assemble all o-rings onto parts dry, without

lubrication. Then apply a thin film of sanitary

lubricant to exposed surfaces of the o-rings.

B.

Lubricate the rear seal area on the auger shaft with

a thin layer of sanitary lubricant. Install the rear

seal o-ring. Lubricate the outside of the rear seal o-

ring with sanitary lubricant.

C.

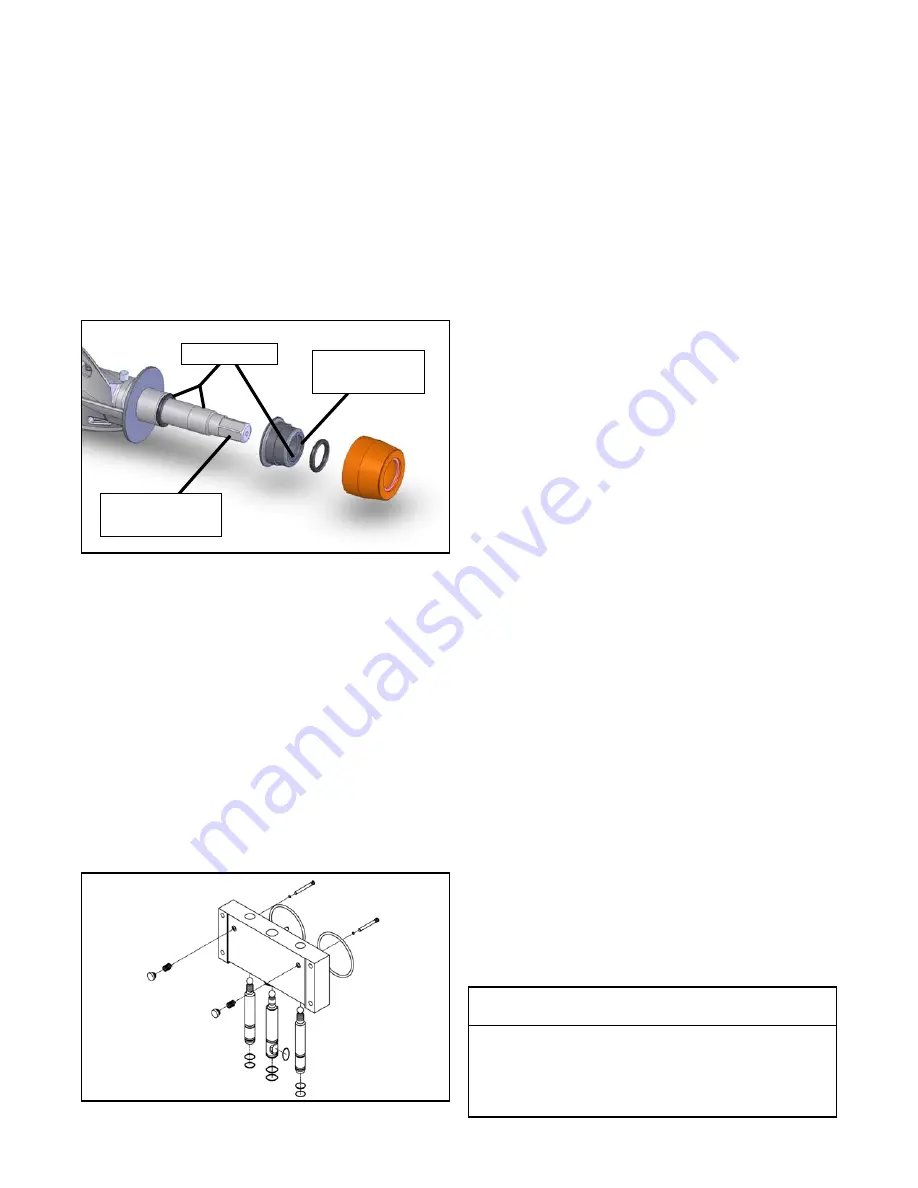

Install the stainless steel rear seal adapter into the

rear seal dry (without lubricant). Lubricate the

inside surface of the rear seal adapter, including

the adapter o-ring, and install it onto the auger

shaft. DO NOT lubricate the outside of the rear seal

adapter (Fig. 3-6).

D.

Lubricate the hex drive end of the auger with a small

amount of hex drive anti seize. A small container

of anti seize is shipped with the machine.

E.

Screw the springs onto the studs in the plastic

flights. The springs must be screwed into the

flights completely to provide proper compression.

F.

Install the two plastic flights onto the rear of the

auger and insert it part way into the freezing

cylinder.

G.

Install the remaining plastic flights, push the auger

into the freezing cylinder and rotate slowly until the

auger engages the drive shaft.

H.

Apply a thin layer of sanitary lubricant to the inside

and outside of the auger support bushing. Install

the bushing onto the auger support and install the

auger support into the front of the auger. Rotate

the auger support so that one leg of the support

points straight up.

H.

Assemble the air bleed valve o-ring onto the air

bleed valve. Position the o-ring into the groove

close to the wide part. Apply a thin film of sanitary

lubricant to the o-ring.

I.

Insert the air bleed valve into the back of the front

door. Install the compression spring onto the air

bleed valve then screw the knob on finger tight.

J.

Apply a thin layer of sanitary lubricant to the o-rings

on the spigot body and install the spigot body

through the bottom of the front door.

K.

Apply a thin film of sanitary lubricant to the door

seal o-ring and fit it into the groove on the rear of

the front door.

M.

Place the front door assembly on the mounting

studs and the push front door against the machine

carefully.

N.

Secure the front door to the machine by placing

the knobs on the studs and tightening until finger

tight. Do not overtighten. Proper o-ring seal can

be observed through the transparent front door.

3.9 SANITIZING

Sanitizing must be done after the machine is clean and just

before the machine is filled with mix. Sanitizing the night

before is not effective. However, you should always clean

the machine and parts after using it.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that all

cleaning and sanitizing solutions used with food pro-

cessing equipment be certified for this use.

When sanitizing the machine, refer to local sanitary regu-

lations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations. Mix sanitizer

according to manufacturer’s instructions to provide a 100

parts per million strength solution. Mix sanitizer in quanti-

ties of no less than 2 gallons of 90°F to 110°F (32°C to

43°C) water. Allow sanitizer to contact the surfaces to be

sanitized for 5 minutes. Any sanitizer must be used only in

accordance with the manufacturer’s instructions.

CAUTION

Risk of Product Damage

Avoid prolonged contact of sanitizer with machine

parts. Sanitizer may cause corrosion of stainless

steel parts if there is prolonged contact.

Figure 3-7 Front Door

Figure 3-6 Rear Seal Assembly

Hex Drive

Anti Seize

Petrol-Gel

Place O-Ring

Inside Insert

Summary of Contents for STOELTING O431RC

Page 1: ...Model O431RC OPERATORS MANUAL Manual No 513664 Rev 2 ...

Page 2: ......

Page 34: ...28 ...

Page 38: ...32 ...