WHILE OPERATING MACHINE

1.

Occasionally look through the clear recovery

tank lid to see if there is any foam build-up. If

excessive foam is found, add defoamer to the

recovery tank.

: Foam must not enter the float shut-

off screen, or damage can occur to the vacuum

motor. Foam will not activate the machines

float shut-off device.

2.

Occasionally view the clear tube at the back

left of the machine to check the amount of

cleaning solution that is left in the machine.

3.

Occasionally check the battery level meter.

(see machine components, item #3) When the

meter is in the red, recharge the batteries.

: When battery meter is in the red, do

not continue to operate the machine. Battery

damage may occur.

4. If the squeegee assembly leaves streaks on the

floor, raise the squeegee off the floor and wipe

the blades down with a damp cloth.

: Do not use your fingers to wipe or

remove debris from the blades, as injury may

occur.

5.

When the solution tank runs empty, turn off

the brush switch, solution switch, and raise the

brush head. Keep the squeegee down and

continue to vacuum until all the dirty water is

picked up. (see TANK DRAINING section to

learn how to drain recovery and solution tanks)

: The brush motors are circuit breaker

protected to protect them from damage. If a

breaker trips, it can't be reset immediately.

You must first determine what caused the

breaker to trip, and allow the motor to cool

down before you can reset the breaker. The

breakers are located on the rear panel of the

control housing.

TANK DRAINING

1.

Turn the power off on the machine

2.

With the squeegee and brush head in their

"up" position, transport the machine to an

approved area for draining the tank(s).

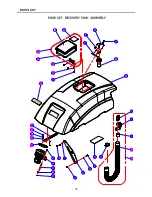

DRAINING THE RECOVERY (DIRTY) TANK

: Anytime scrubbing is completed, or

when refilling the solution tank, the recovery

tank should also be drained and cleaned.

: If the recovery tank is not drained

when the solution tank has been refilled, foam

or water may enter the float shut-off

mechanism and cause damage to the vacuum

motor.

1.

Remove the drain hose from the holder and

place the drain hose over a floor drain. Twist

off the drain hose plug to begin the draining

process. In order to completely empty the

recovery tank, hinge open the recovery tank

and let it rest on the support stand.

2.

Clean the recovery tank after every use. Use a

fresh water hose to rinse out the inside of the

tank. Be careful not to spray water into the

float shut- off mechanism.

: If you are storing the machine for any

period of time, always leave the clear recovery

tank lid off the tank so the tank may dry

completely, and smell fresh.

3.

Replace the drain hose plug tightly as soon as

you are done draining the tank.

7