MACHINE SET UP & INSTALLATION

UNCRATING MACHINE

Be sure and check packing carton for any damage.

Immediately report any damage to carrier. Check

contents of package to ensure that the following

items are included: Machine, batteries (x6),

squeegee assembly, battery charger and pad

drivers. (Batteries and charger may be on separate

skid)

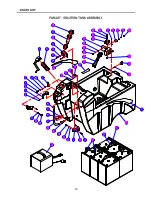

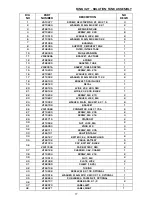

BATTERY CONNECTIONS

The batteries and charger are shipped separately

and will need to be installed and connected as

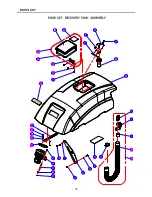

shown in the diagram below.

: Batteries emit hydrogen gas.

Explosion or fire can result from hydrogen gas.

Keep sparks and open flames away! Keep

battery compartment open while charging.

1.Be sure the power switch is in the "off" position.

2.

Open recovery tank to gain access to battery

compartment.

3.

Carefully place the six batteries into the

compartment as shown in figure below. Place

the battery brace at the rear of the batteries.

4.

Connect battery cables to posts in order as

shown in diagram below. (RED to POSITIVE

and BLACK to NEGATIVE)

5.

Apply a coating or protective spray on the

cable connections to prevent battery corrosion.

DO NOT DROP THE BATTERIES INTO

COMPARTMENT!

MACHINE SET UP

PRE-OPERATION CHECKS

1.

Sweep or dust mop the surface to be cleaned.

2.

Check battery meter to make sure batteries are

fully charged. (SEE BATTERY CHARGING)

3.

Ensure squeegee is properly installed.

4.

Ensure that brush/pad is properly installed.

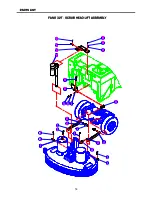

INSTALLING PAD DRIVERS OR BRUSHES

1.

Ensure the machine is turned off.

2.

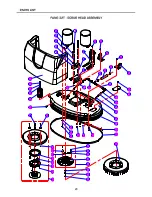

Raise the brush head assembly off the floor by

pushing on the brush lift button on the control

console.

3.

Slide back the viewing window panel on the

aluminum deck housing.

4.

If using a pad driver, first attach the

appropriate pad to the bottom of the driver.

5.

Slide the pad driver under the deck and look

through the viewing panel and line the three

lugs with the three holes in the drive motor

hub. Once in the holes, rotate the driver

toward the spring clip to lock the driver in

place

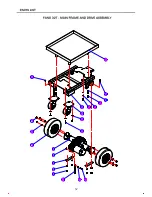

MOUNTING THE SQUEEGEE

1.

Pull the squeegee lift lever to raise the

squeegee bracket up.

2.

Loosen the two knobs on the squeegee and

slide the squeegee into the slots at the rear of

the squeegee bracket. (the wheels on the

squeegee point to the back)

3.

Tighten the knobs securely.

4.

Secure the vacuum hose on the pick-up tube

of the squeegee.

5