- 4 -

Features and Specifications

Purpose of the cooling units

•

WM-4510~8510HZD cooling units are designed and used to provide a

stable temperature between 50~65

°

F for a properly insulated and sized

space.

•

The refrigerated space will maintain humidity within the range of 50~70%

RH.

•

These temperature and humidity ranges like in natural caves are

optimized for long term storage of wine.

Specialty of design

•

The unit is self-contained and all-in-one ready for use. No copper tubing

and drain line are required.

•

Innovative

control programming can adjust the humidity without an

external

humidifier.

•

Both curved supply grille and front panel bring you dynamic style.

•

Backward-curved impeller fans can duct the supply air and exhaust air

each 50 ft in total.

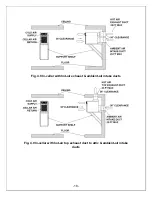

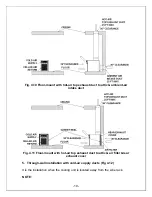

Flexibility of installation

•

Adjustable speed evaporator fan allows for flexible installations: standard

through-wall, through-wall with ductworks, in-cellar with ductworks and

remote-mount with ductworks.

•

Quiet and high speed condenser exhaust fan selection makes it work at

both normal and extremely high ambient temperatures.

Availability of options

•

Crankcase heater protects the compressor from slugging damage when

the ambient temperature falls below 50

°

F.

•

Low cellar temperature activated cellar heater outlet for an electric heater

can be used in extreme low temperature condition to protect your wine

from freezing.

•

Low and high cellar temperature activated phone notification allows your

expensive wine protected all the time.

•

An independent humidifier can be hooked up to maintain the proper

humidity as the customer requires in extremely dry conditions.

•

Reusable condenser air filter keeps the condenser clean and maintains

the cooling unit running efficiently.

•

Optional left or right towards supply grille, top exhaust, side or rear power

cord can meet your customized air supply and installation requirements.

The specifications and dimensions are listed as follows:

Summary of Contents for Wine-Mate WM-4510HZD

Page 24: ...23 Fig 4 15 Cold air supply cellar air return and hot air exhaust ducts...

Page 29: ...28 Electrical Wiring Diagrams Fig 7 1 WM 4510 8510HZD standard wiring diagram...

Page 30: ...29 Fig 7 2 WM 4510 8510HZD crankcase heater wiring diagram...

Page 31: ...30 Fig 7 3 WM 4510 8510HZD alarm call wiring diagram...

Page 32: ...31 Fig 7 4 WM 4510 8510HZD cellar heater wiring diagram...

Page 33: ...32 Fig 7 5 WM 4510 8510HZD crankcase heater alarm call wiring diagram...

Page 34: ...33 Fig 7 6 WM 4510 8510HZD crankcase heater cellar heater wiring diagram...

Page 35: ...34 Fig 7 7 WM 4510 8510HZD alarm call cellar heater wiring diagram...

Page 36: ...35 Fig 7 8 WM 4510 8510HZD crankcase heater alarm call cellar heater wiring diagram...