BULLETIN

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: [email protected]

CARE AND HANDLING

OF SPRINKLERS

Page 4 of 4

Form No. F_091699 18.10.11 Rev 16.1.P65

USE THE FOLLOWING PRECAUTIONS WHEN HANDLING WAX-COATED SPRINKLERS

Many of Viking’s sprinklers are available with factory-applied wax coating for corrosion resistance. These sprinklers MUST receive

appropriate care and handling to avoid damaging the wax coating and to assure satisfactory performance of the product.

General Handling and Storage of Wax-Coated Sprinklers:

•

Store the sprinklers in a cool, dry place (in temperatures below the maximum ambient temperature allowed for the sprinkler temperature rating. Refer

to Table 1 below.)

•

Store containers of wax-coated sprinklers separate from other sprinklers.

•

Protect the sprinklers during storage, transport, handling, and after installation.

•

Use original shipping containers.

•

Do not place sprinklers in loose boxes, bins, or buckets.

Installation of Wax-Coated Sprinklers:

Use only the special sprinkler head wrench designed for installing wax-coated Viking sprinklers (any other wrench may damage

the unit).

•

Take care not to crack the wax coating on the units.

•

For touching up the wax coating after installation, wax is available from Viking in bar form. Refer to Table 1 below. The coating MUST be repaired after

sprinkler installation to protect the corrosion-resistant properties of the sprinkler.

•

Use care when locating sprinklers near fixtures that can generate heat. Do not install sprinklers where they would be exposed to temperatures exceed-

ing the maximum recommended ambient temperature for the temperature rating used.

•

Inspect the coated sprinklers frequently soon after installation to verify the integrity of the corrosion resistant coating. Thereafter, inspect representative

samples of the coated sprinklers in accordance with NFPA 25. Close up visual inspections are necessary to determine whether the sprinklers are being

affected by corrosive conditions.

Never install sprinklers that have been dropped, damaged, or exposed to temperatures in excess of the maximum ambi-

ent temperature allowed.

Refer to the appropriate current technical data pages for complete care, handling, and installation instructions. Data

pages are included with each shipment from Viking or Viking distributors. They can also be found on the Web site at www.

vikinggroupinc.com.

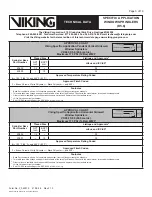

TABLE 1

Sprinkler Temperature Rating

(Fusing Point)

Wax Part

Number

Wax Melting Point

Maximum Ambient

Ceiling Temperature

1

Wax Color

155 °F (68 °C) / 165 °F (74 °C)

02568A

148 °F (64 °C)

100 °F (38 °C)

Light Brown

175 °F (79 °C)

04146A

161 °F (71 °C)

150 °F (65 °C)

Brown

200 °F (93 °C)

04146A

161 °F (71 °C)

150 °F (65 °C)

Brown

220 °F (104 °C)

02569A

170 °F (76 °C)

150 °F (65 °C)

Dark Brown

286 °F (141 °C)

02569A

170 °F (76 °C)

150 °F (65 °C)

Dark Brown

1

Based on NFPA-13. Other limits may apply, depending on fire loading, sprinkler location, and other requirements of the Authority Having

Jurisdiction. Refer to specific installation standards.

Replaces Form No. F_091699 Rev 16.1

(Added P65 Warning)