SECTION TSM 151.2

ISSUE B

PAGE 9 OF 14

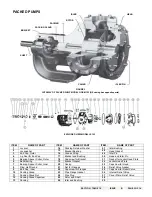

FIGURE 5 – STANDARD MECHANICAL SEAL

FIGURE 6

ASSEMBLY

Standard Mechanical Seal

(Synthetic Rubber Bellows Type)

The seal used in this pump is simple to install and good

performance will result if care is taken during installation.

The principle of the mechanical seal is contact between the

rotary and stationary members. These parts are lapped to a

high finish and their sealing effectiveness depends on

complete contact.

A number of heavy-duty pumps are furnished with special

mechanical seals. These special seals are not discussed in

TSM 151.2. Information is available by contacting the

factory. When requesting special seal information, be sure

to give pump model number and serial number.

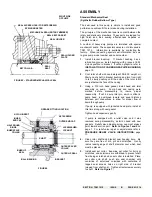

1.

Install bracket bushing. If bracket bushing has a

lubrication groove, install bushing with groove at 6:00

o’clock position in bracket. If carbon graphite, refer to

INSTALLATION OF CARBON GRAPHITE BUSHINGS,

page 12.

2.

Coat rotor shaft with non-detergent SAE 30 weight oil.

Start end of shaft in bracket bushing and turn from right

to left, slowly pushing until the ends of the rotor teeth

are just below the face of the casing.

3.

Using a .015 inch head gasket, install head and idler

assembly on pump. Pump head and casing were

marked before disassembly to insure proper

reassembly. If not, be sure idler pin, which is offset in

pump head, is positioned toward and equal distance

between port connections to allow for proper flow of

liquid through pump.

If pump is equipped with jacketed head plate, install at

this time along with new gasket.

Tighten head capscrews gently.

If pump is equipped with a relief valve and it was

removed during disassembly, install on head with new

gaskets. Relief valve adjusting screw cap must always

point toward suction port.

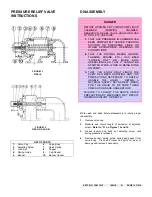

Refer to Figures 1 and 2

on

page 1. For relief valve repair or adjustments, refer to

PRESSURE RELIEF VALVE INSTRUCTIONS,

page

13.

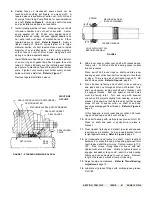

4.

Clean rotor shaft and bracket seal housing bore. Be

sure they are free of dirt, grit and scratches. Gently

radius leading edge of shaft diameter over which seal

must be placed.

5.

Install seal set collar. Examine set collar for burrs or

scratches, and setscrews are withdrawn to prevent shaft

from being scratched when set collar is installed. Place

set collar onto shaft, push into seal chamber until

centerline of setscrews coincides with centerline of

tapped seal access holes on right side of bracket

(viewed from shaft end). Tighten all setscrews securely

to shaft.

Refer to Figure 7.

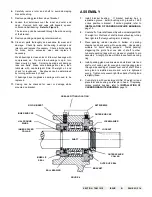

SET

COLLAR

SEAL

SEAT

SPRING ADAPTER

SEAL ACCESS HOLE (FOR SETSCREWS)

MECHANICAL SEAL (ROTARY MEMBER)

SEAL SEAT GASKET

SEAL HOLDER

SEAL HOLDER

PLATE

RIGHT SIDE

OF PUMP

GREASE FITTING LOCATION

SETSCREWS

OUTER END CAP

LOCKWASHER

LOCKNUT

BRACKET

OUTER LIP SEAL

OUTER SPACER

COLLAR

SHAFT

INNER SPACE

COLLAR

HALF ROUND

RINGS

INNER

END CAP

NYLON INSERT

INNER LIP

SEAL

BALL BEARING