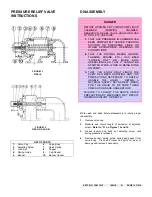

6.

Sealing faces on mechanical seals should not be

touched with anything but fingers or a clean cloth. A

tapered sleeve is available, at extra cost, for Q, QS and

M pumps from Viking Pump Division for seal installation

on shaft.

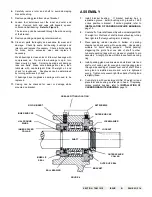

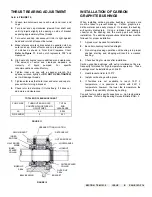

Refer to Figure 8

. LS pump shaft is tapered

and an installation sleeve is not available.

7.

Install rotating member of seal. Slide spring over shaft

into seal chamber and onto set collar pilot. Center

spring adapter (Q, QS, M size only) against back of

metal retainer so spring will push against adapter and

not work itself over back of mechanical seal. Place

tapered sleeve on shaft.

Refer to Figure 8

. Apply a

liberal coating of SAE-30 non-detergent oil to large

diameter portion of shaft, tapered sleeve and to inside

diameter of seal rubber parts. Start rotary member,

carbon face out, onto shaft and push along shaft until

spring is centered against adapter.

Install Stationary Seal Seat. Lubricate outside diameter

of seal o-ring seat gasket and flush lapped face with

lube oil. Press stationary seat by installing seal holder

and secure to machined face of bracket with seal holder

plate. Tighten nuts securing seal holder evenly so seal

holder will not be distorted.

Refer to Figure 7

.

Remove tapered installation sleeve.

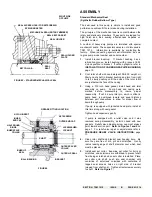

8.

Slide inner spacer collar over shaft with recessed end

facing rotor. Q, QS and M size bearing spacer collars

are not recessed.

Place pair of half round rings on shaft and slide inner

bearing spacer collar over half round rings to lock them

in place. There is no pair of half round rings on Q, QS

and M size pumps

. Refer to Figure 6

, page 9.

9.

Press lip seal, lip facing end of shaft, in inner end cap

and insert end cap through shaft end of bracket. Turn

end cap clockwise, looking at shaft end of bracket, until

it engages threads. End cap spanner wrench holes

must be facing rotor. Turn end cap with spanner

wrench until it projects slightly from opening on side of

bracket. End cap must not be turned so far that lip seal

drops off end of spacer collar on shaft or end cap

becomes disengaged from threads.

Refer to Figure 6,

page 9.

If this happens, remove inner spacer collar, half round

rings and end cap and start over at Step 8.

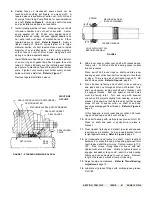

10.

Pack ball bearing with multi-purpose grease, NLGI #2.

Place on shaft and push or gently drive in place in

bracket.

11.

Press lip seal, lip facing end of shaft, in outer end cap and

insert end cap in bracket. Turn end cap in bracket until it

is tight against bearing.

Refer to Figure 6

, page 9.

12.

Put lockwasher and locknut on shaft. Insert length of

hardwood or brass through port opening between rotor

teeth to keep shaft from turning. Tighten locknut to 170-

190 - ft.lbs. torque. If tang does not line up with slot,

tighten locknut until it does. Failure to tighten locknut or

engage lockwasher tang could result in early bearing

failure and cause damage to rest of pump. Remove

length of hardwood or brass from port opening.

13.

Adjust pump end clearance.

Refer to Thrust Bearing

Adjustment,

page 12.

14.

Lubricate all grease fittings with multi-purpose grease,

NLGI #2.

SECTION TSM 151.2

ISSUE B

PAGE 10 OF 14

FIGURE 8

FIGURE 7 – STANDARD MECHANICAL SEAL

SET COLLAR

SEAL

SEAT

SEAL HOLDER

PLATE

SEAL HOLDER

SEAL SEAT GASKET

SEAL ACCESS HOLE (FOR SETSCREWS)

SPRING ADAPTER

MECHANICAL SEAL (ROTARY MEMBER)

RIGHT SIDE

OF PUMP

COAT WITH LIGHT OIL

BEFORE ASSEMBLY

TAPERED SLEEVE

SPRING

MECHANCIAL SEAL

(ROTARY MEMBER)