piping system at test pressures equal to or less than 14˝

w.c. (3.5 kPa).

Unions and manifold have been factory-tested. Leak

test must be repeated during initial trial operation of

burner by mechanical contractor.

Never check for gas leaks with an open flame. Use

approved liquid spray solution for bubble test. Follow

Fig. 14 whenever gas valve is replaced.

Proper piping practice

Support piping by proper suspension method. Piping

must not rest on or be supported by boiler.

7.4

Boiler piping in heating/cooling application

The boiler, when used in connection with a refrigeration

system, must be installed so the chilled medium is

piped in parallel to the boiler with appropriate valves to

prevent the chilled medium from entering the boiler

(Fig. 15).

The boiler piping system of a hot water heating boiler

connected to heating coils located in air handling units

where they may be exposed to refrigerated air

circulation must be equipped with flow control valves or

other automatic means to prevent gravity circulation of

the boiler water during the cooling cycle.

Check installation instructions of chiller manufacturer

carefully for additional requirements.

Cooling season starts: Close valve V1 and open

valve V2.

Heating season starts: Close valve V2 and open

valve V1.

A metal tag should be attached to these valves as to

purpose.

Note:

In the above system, the circulating pump must be

operated from a separate on/off switch – not from the

pump aquastat on the boiler!

7.5

Main burner

Proper flame:

Upper main flame cone with light

orange coloring, sharply defined

individual flames.

Underfired:

Lazy-burning main flame cone,

mushy flame appearance throughout,

smaller flame sizes than in Fig. 16.

Overfired:

Increased burner noise, higher flame

sizes than Fig. 16.

7.6

Pilot burner

Proper flame:

Upper main flame cone with light orange

coloring, sharply defined individual flame.

12

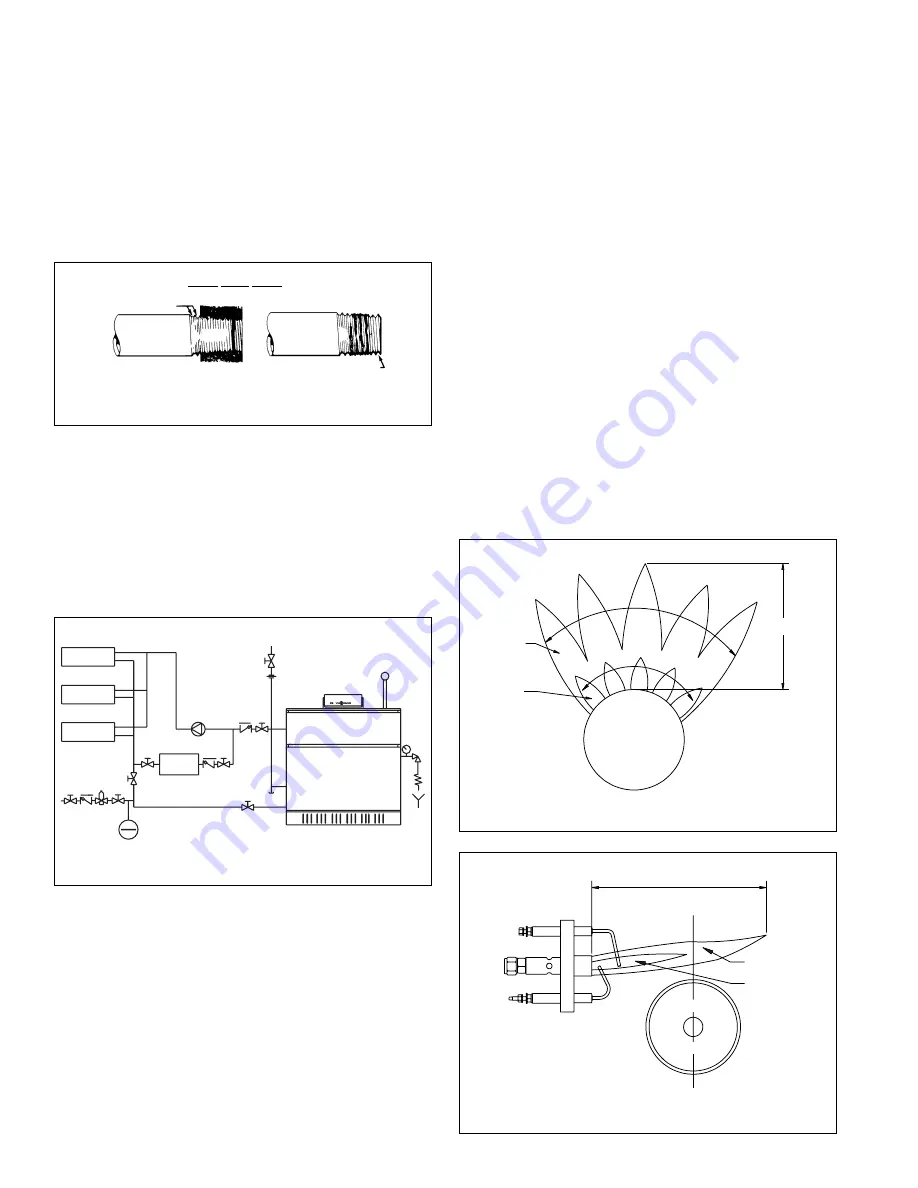

Fig. 14

Gas piping into gas valve

Fig. 15

Boiler piping in a heating/cooling application

Heating/

cooling unit

Water

chiller

Heating/

cooling unit

Heating/

cooling unit

V

FC AFV

V

V2

CP

FC

V

FC

V

PRV

V1

Fig. 16

Front view – single burner

Main flame cone

Inner flame cone

Light blue

Blue

Burner

7˝

Fig. 17

Side view – pilot burner

6˝

(150mm)

Ionization

electrode

Pilot

burner

Ignition

electrode

Main burner

Orange outer

flame cone

Blue inner

flame cone

2 imperfect

threads

Thread pipe correct length, leave 2 end threads bare.

Use moderate amount of dope

Pipe

Control

Proper piping practice