23

Selected gas type

Gas

type

Date

CO

2

content in

%

O

2

content in % CO content in

ppm

Delivered condition

G 20

7.5 - 10.5

< 1000

Changed to

< 1000

Changed to

< 1000

Checking the static pressure and supply pressure

Danger

CO formation as a result of incorrect burner

adjustment can have serious health implications.

Check the CO content before and after carrying

out work on gas appliances.

Operation with LPG

Purge the LPG tank twice on commissioning or

replacement. Vent the tank and gas connection line

thoroughly after purging.

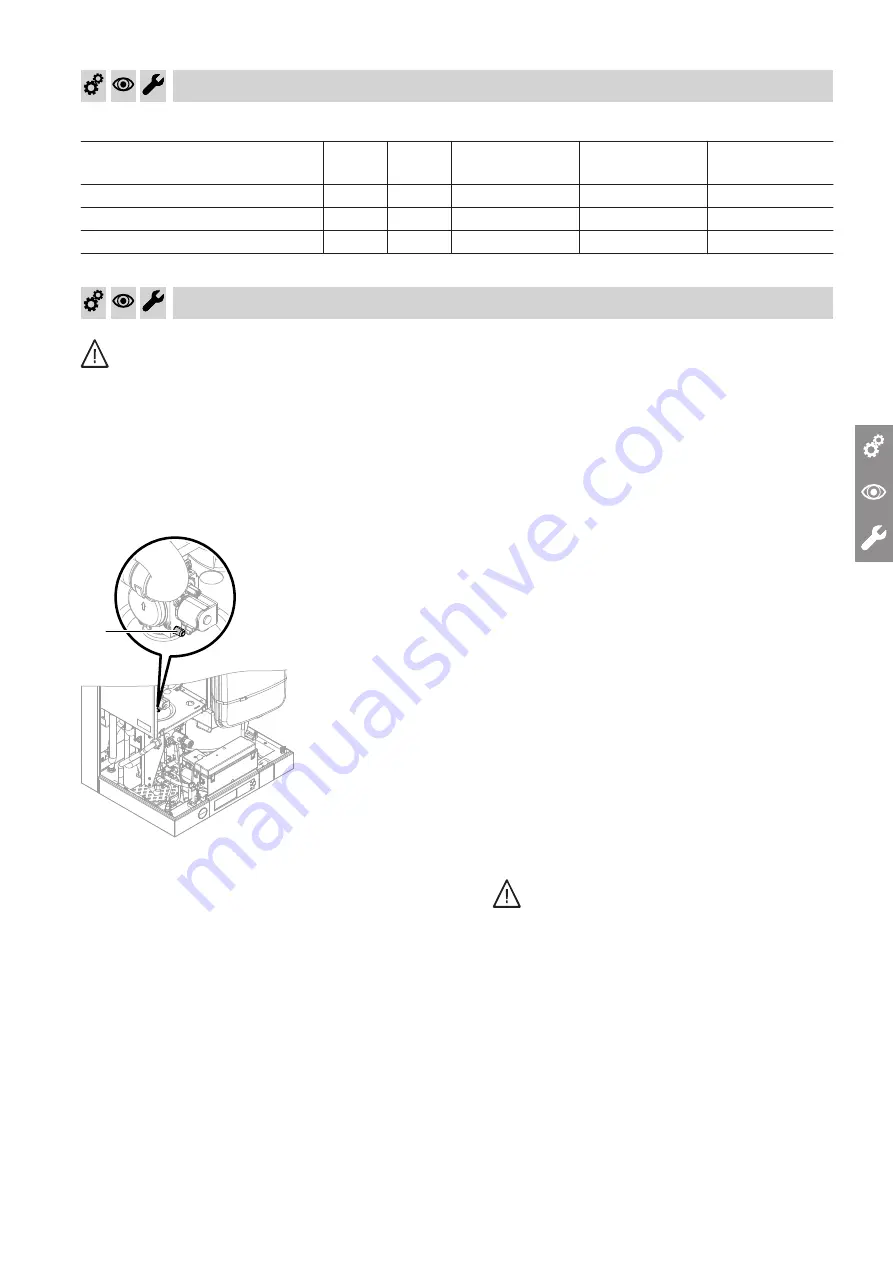

A

Fig. 18

1.

Close the gas shut-off valve.

2.

Undo screw

A

inside test connector "IN" on the

gas train, but do not remove it. Connect the pres-

sure gauge.

3.

Open the gas shut-off valve.

4.

Check the static pressure.

Set value: max. 57.5 mbar (5.75 kPa)

5.

Start the boiler.

Note

During commissioning, the appliance can enter a

fault state because of airlocks in the gas line. After

approx. 5 s, tap and hold

"R"

for approx. 2 s to

reset the burner.

Ensure that enough heat is being drawn during the

testing and setting processes.

6.

Check the supply (flow) pressure.

Set value:

■

Natural gas: 20 mbar (2.0 kPa)

■

LPG: 50 mbar (5.0 kPa)

Note

Use a suitable tester with a resolution of at least

0.1 mbar (10 Pa) to check the supply pressure.

7.

Implement measures as indicated in the table

below.

8.

Shut down the boiler and close the gas shut-off

valve. Remove the pressure gauge and seal test

connector

A

with screw.

9.

Open the gas shut-off valve and start the appli-

ance.

Danger

Gas escaping from the test connector leads

to a risk of explosion.

Check gas tightness at test connector

A

.

Note

The maximum pressure drop between the gas shut-off

valve and test connector

A

at the gas train is

0.5 mbar (50 Pa).

Commissioning, inspection, maintenance

Changing the gas type

(cont.)

5697789

Summary of Contents for Vitodens 111-W

Page 5: ...5 13 Keyword index 58 Index Index cont 5697789...

Page 59: ...59 5697789...