ESS3/ESS4

- 6 -

SECTION 1

All of these recommended components are available together in convenient repair kits for

your ESS3 or ESS4 model Regulator:

Repair Kit

Part No.

Description

RK-ESS3-HP

0790-0162

ESS3 Repair Kit for Oxygen, Inert Gases, Air, CO

2

,

N

2

O, Hydrogen.

RK-ESS4-HP

0790-0163

ESS4 Repair Kit for Oxygen, Inert Gases, Air, CO

2

,

N

2

O, Hydrogen.

RK-ESS4-HP200

0790-0164

ESS4 Repair Kit - 200 PSIG Delivery Models Only -

for Oxygen, Inert Gases, Air, CO

2

, N

2

O, Hydrogen.

RK-ESS3-F

0790-0165

ESS3 Repair Kit for Acetylene, LP Gas.

RK-ESS4-F

0790-0166

ESS4 Repair Kit for Acetylene, LP Gas.

CLEANING PARTS

It is recommended to clean all metal parts for oxygen service, regardless of Regulator Model

being repaired. There are several ways to clean components for oxygen service; the

following standards are recommended reading for more detailed information on methods and

processes:

•

CGA G-4.1 “Cleaning Equipment for Oxygen Service”

•

ASTM G-93 “Standard Practice for Cleaning Methods and Cleanliness Levels for

Material and Equipment Used in Oxygen-Enriched Environments”

•

ASTM G-127 “Standard Guide for the Selection of Cleaning Agents for Oxygen

Systems”

For metal parts, Victor brand suggests using CCI Envirospray Liquid, used per the

manufacturer's instructions, followed by a hot water rinse and thorough drying. Additional

information can be found at

.

DO NOT

allow non-metal parts to come in contact with cleaning solvents. Cleaning solvents

can cause non-metal parts to swell and/or crack. To clean these parts, use a non-petroleum

based mild soap solution, followed by a thorough rinsing in water. Dry parts completely prior

to reassembling.

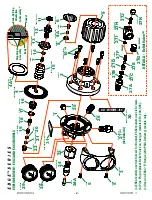

ASSEMBLY PROCEDURES

Refer to the exploded view for reference numbers [Shown in brackets]

IMPORTANT NOTES ABOUT SEALING PIPE THREADS:

•

When using Teflon® tape where noted: Apply two to three layers around the

threads, leaving the first thread clean. Insure your Teflon® tape is oxygen-

compatible.

•

When using Loctite® #222 Threadlocker where noted: Apply two to three drops

to the second and third thread, leaving the first thread clean.